thepope540

Member

- :

- 2003.5 Yellow Speed - Sold, Spicy - Sold, #639 Black Mica

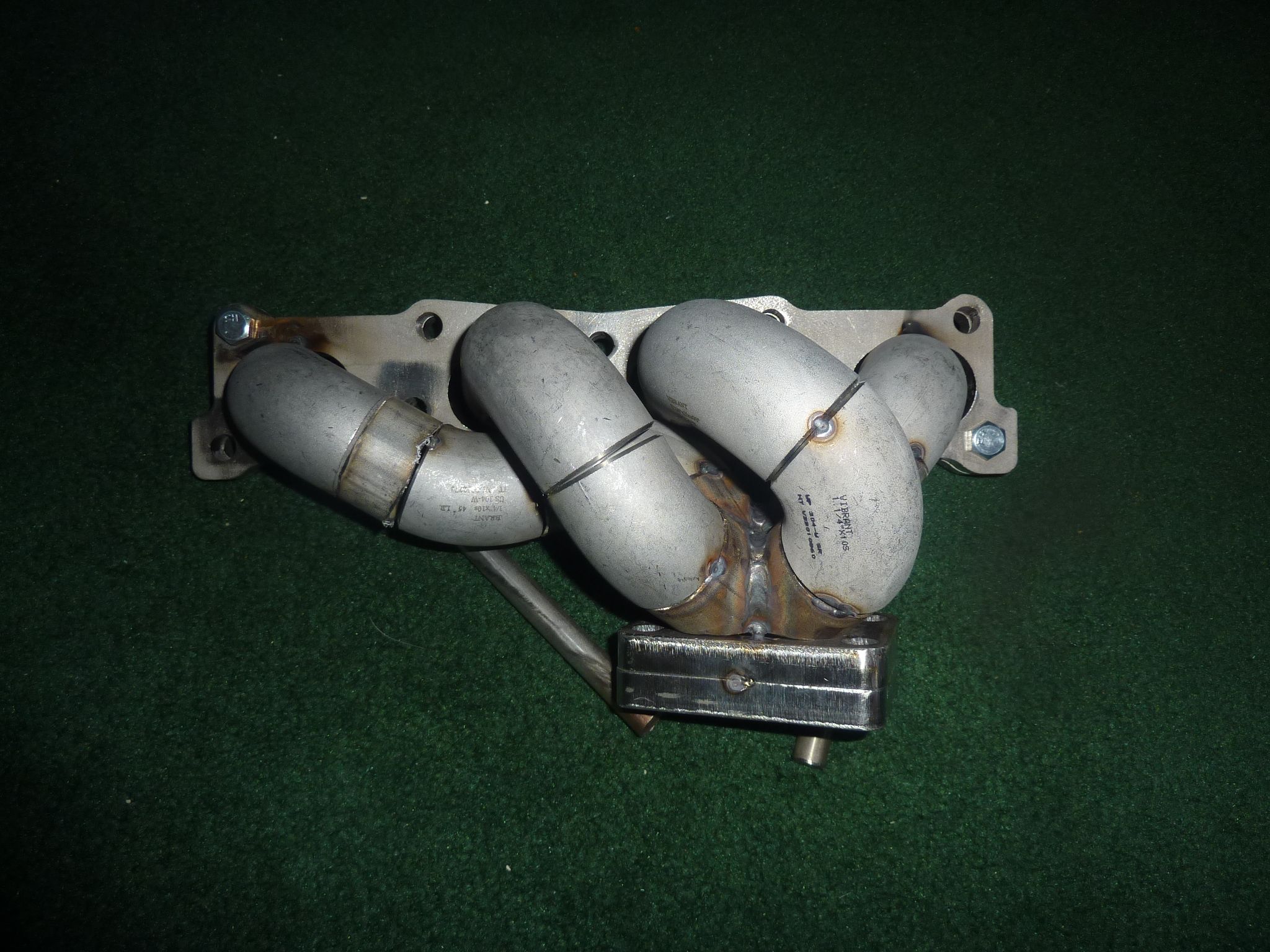

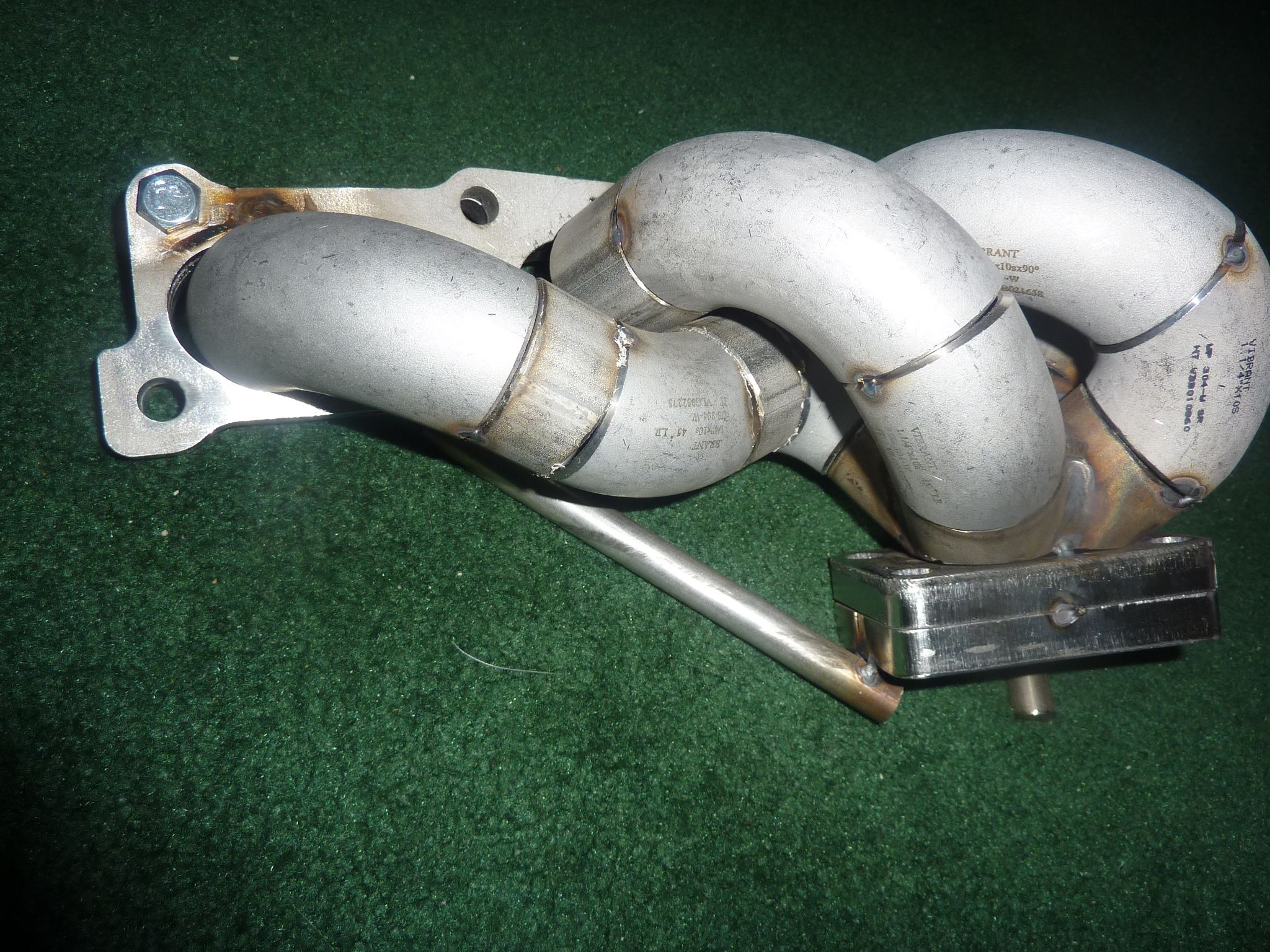

The manifold will be $475 shipped for a base manifold. O2 is a $25 option. EGR will be a $25 option, and EWG will be a $50 option. For those interested in EWG, I'll also be offering a simple dump tube but I haven't even started looking at that yet.

The manifold is all 304SS, 1/2" flanges, and schedule 10 pipe for a good solid construction. I'll have more pics as the prototype is refined and gets final assembly.

The manifold is all 304SS, 1/2" flanges, and schedule 10 pipe for a good solid construction. I'll have more pics as the prototype is refined and gets final assembly.

Last edited: