I just read through your build and it is pretty inspiring. I have a very love/hate relationship with my p5 but I think I want to start taking it a little bit more seriously. I was wondering if you could recommend an aftermarket clutch set. In the winter, it was replaced w/ a Duralast kit (out of necessity) and I am not happy with it at all.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zack Mac's P5

- Thread starter zackmac

- Start date

I just read through your build and it is pretty inspiring. I have a very love/hate relationship with my p5 but I think I want to start taking it a little bit more seriously. I was wondering if you could recommend an aftermarket clutch set. In the winter, it was replaced w/ a Duralast kit (out of necessity) and I am not happy with it at all.

Thanks! I got this P5 completely stock and have been building ever since

I still run the original factory clutch. It's definitely not going to last much longer (@117k)

In the MSP I replaced the clutch with an Exedy Stage I, but then totaled the car only a few days after that, so I don't really have enough experience to recommend or review it.

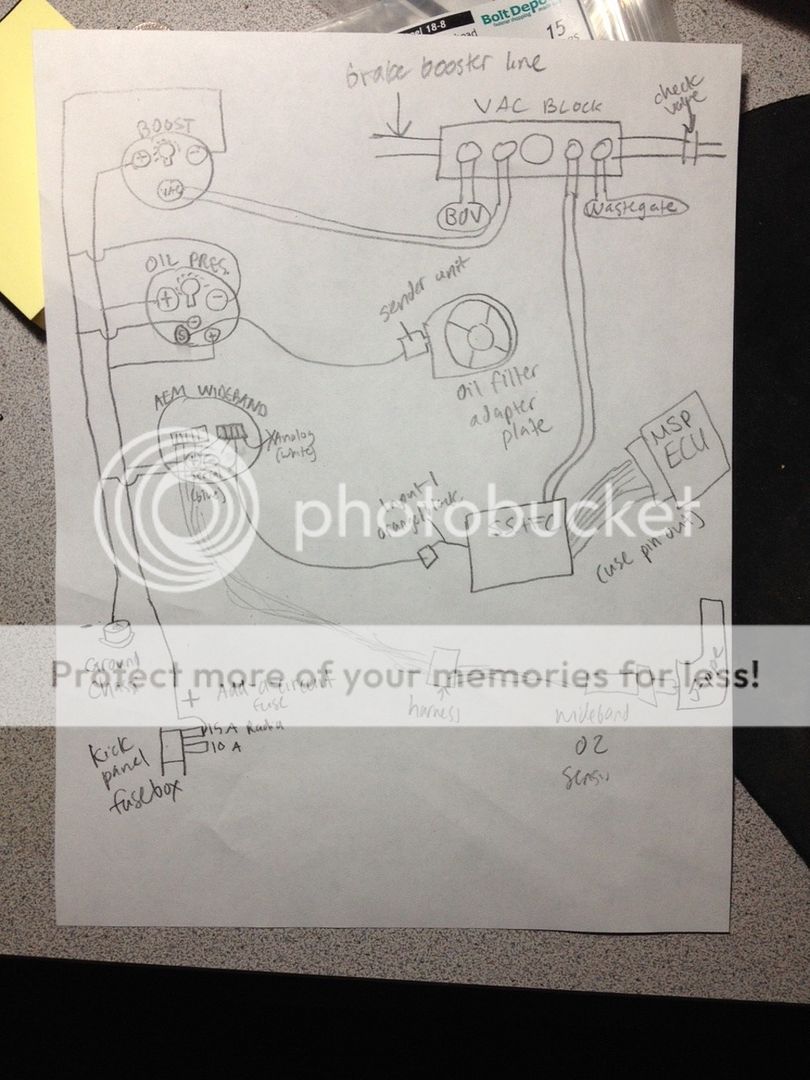

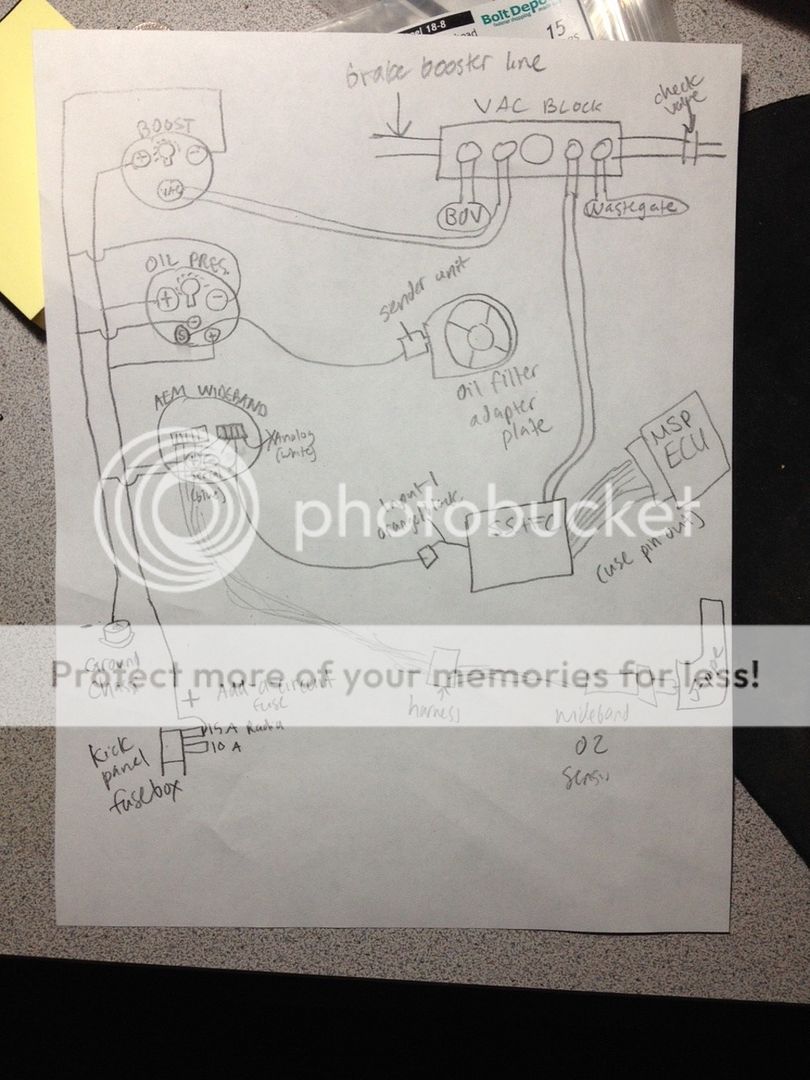

quick little update of the gauges installed

and here is a very useful diagram i created, took a few hours of research to piece this together.. some of you may already know this since it is pretty basic stuff but it will also help a lot of people out there looking to install gauges

ill try to find time to update an engine bay pic tomorrow of the painted valve cover and washer dressup kit from cr3

and here is a very useful diagram i created, took a few hours of research to piece this together.. some of you may already know this since it is pretty basic stuff but it will also help a lot of people out there looking to install gauges

ill try to find time to update an engine bay pic tomorrow of the painted valve cover and washer dressup kit from cr3

my clutch is on its last leg... looking to upgrade when i replace. i had an exedy stage 1 on the msp for a few weeks before i totaled it, would it be worth going this option again? also, thoughts on a lighter flywheel and msp lsd weld?

also need to find a new solution for the turbo oil return. i am using the recommended setup from the "thinking of turbocharging your p5" thread, with a high temp silicone hose mated with a fitting welded in my oil pan. i had it welded as high as possible but it is seeping out oil increasingly faster now between the fitting and the hose. tried a hose clamp with no success. i don't have the windage tray, could it be i chose a bad spot to weld the fitting? i did it opposite side of the drain plug as high as possible and the nipple is parallel to the ground.. thinking maybe it should be angled up. anyways i dont know the resting oil line in the pan. what did you guys do/what would you recommend?

additionally on the list of things to look into...

--- headlights cutting out at 5.5k+ rpms... battery is new, i think it must be alternator? no idea. i have new battery terminals and a 1/0g wire kit to install in the bay, maybe that will help

--- not building boost beyond 1-2 psi. thinking it could be wastegate actuator improperly aligned (rod sticks out too far, seal/flap can't close to build pressure?), bad silicone coupler connection, bad ebay type rs bov... idk yet

also need to find a new solution for the turbo oil return. i am using the recommended setup from the "thinking of turbocharging your p5" thread, with a high temp silicone hose mated with a fitting welded in my oil pan. i had it welded as high as possible but it is seeping out oil increasingly faster now between the fitting and the hose. tried a hose clamp with no success. i don't have the windage tray, could it be i chose a bad spot to weld the fitting? i did it opposite side of the drain plug as high as possible and the nipple is parallel to the ground.. thinking maybe it should be angled up. anyways i dont know the resting oil line in the pan. what did you guys do/what would you recommend?

additionally on the list of things to look into...

--- headlights cutting out at 5.5k+ rpms... battery is new, i think it must be alternator? no idea. i have new battery terminals and a 1/0g wire kit to install in the bay, maybe that will help

--- not building boost beyond 1-2 psi. thinking it could be wastegate actuator improperly aligned (rod sticks out too far, seal/flap can't close to build pressure?), bad silicone coupler connection, bad ebay type rs bov... idk yet

Last edited:

MeAndMyPenguin

Member

- :

- 2002.5 Mazdaspeed Protege5

Do you think you can take more pics of what you did with the ac cylinder to fit the intercooler pipe? Kinda confused on that part.

Do you think you can take more pics of what you did with the ac cylinder to fit the intercooler pipe? Kinda confused on that part.

there are 2 brackets over the ac cylinder that hold it in place. i removed both of those and carefully bent the ac lines until the cylinder was angled and out of the way.

i then was able to use the brackets and self tapping screws to secure it in its new location

just be careful bending the lines

Similar threads

- Replies

- 3K

- Views

- 329K