The mail lady knocked on the door. I had several packages from overseas that I had to sign for. Here were the big ones:

One of the boxes had some dings, I documented same just in case:

The parts were well packed so I felt a little better about things (note, Japanese cardboard is pretty flimsy compared to ours):

Liberated from the boxes, but not yet fully unpacked:

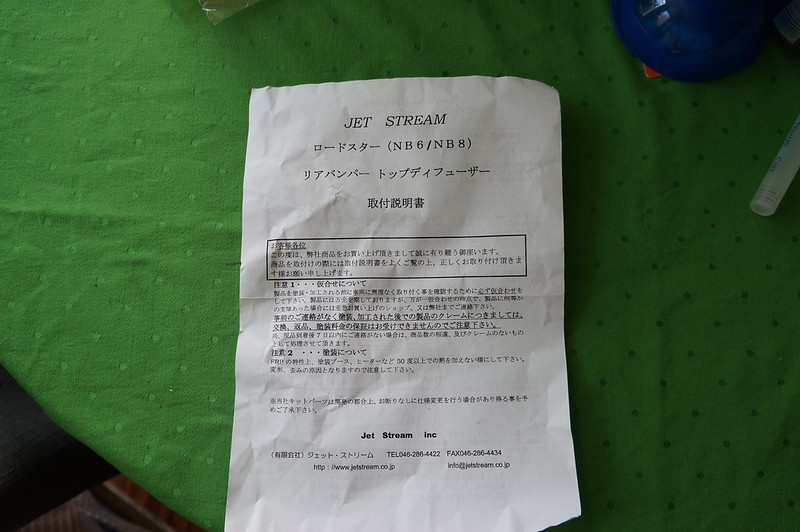

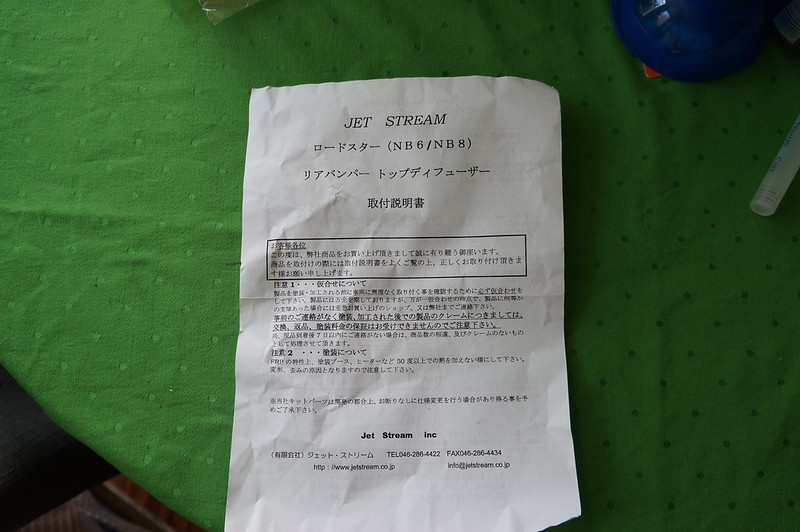

JDM yo. Any translators in the house?

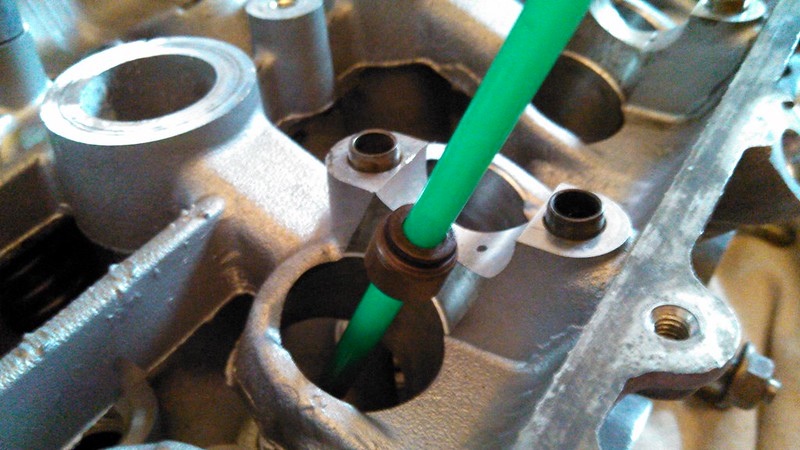

If you want to know if you have an actual real-deal product, look for the manufacturer's mark:

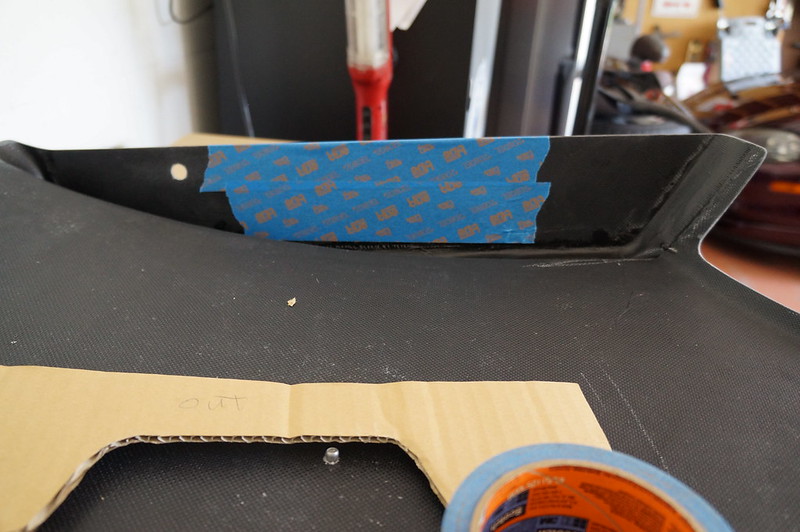

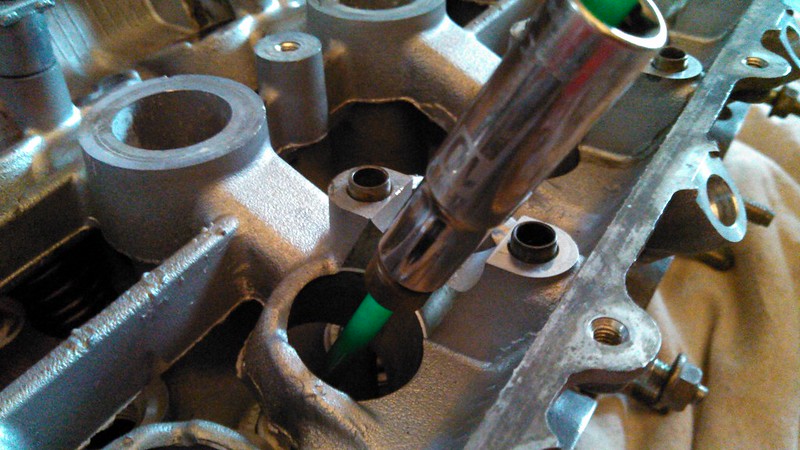

Here's the top of the lower piece, can you tell what it is?

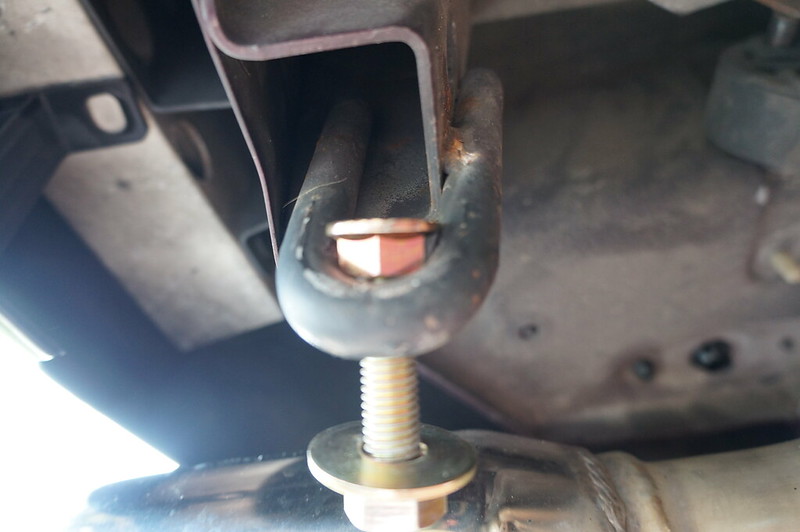

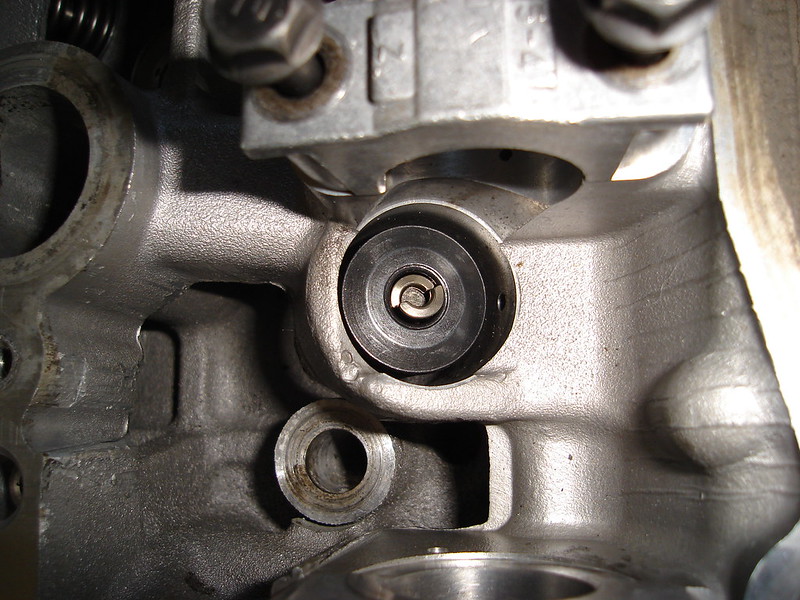

The bottom:

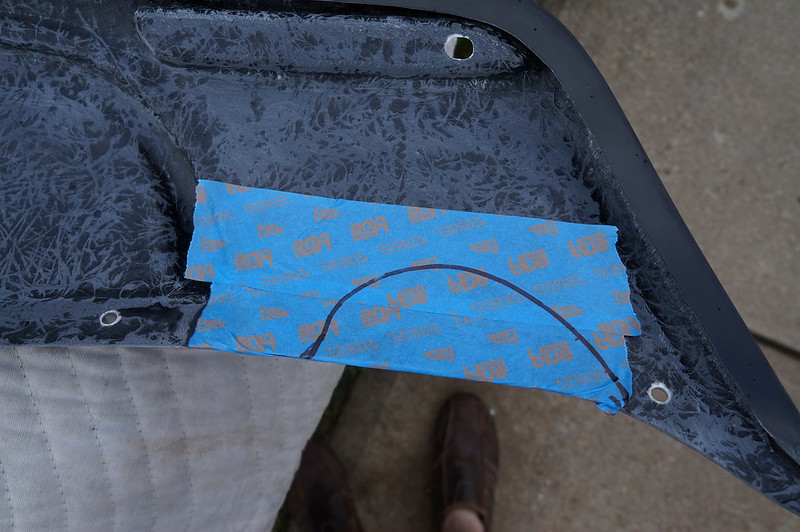

And for the grand finale...

That shot has the piece upside-down, just stand on your head to see how it will look. I'll wait while the blood rushes to your head and you pass out.

One of the boxes had some dings, I documented same just in case:

The parts were well packed so I felt a little better about things (note, Japanese cardboard is pretty flimsy compared to ours):

Liberated from the boxes, but not yet fully unpacked:

JDM yo. Any translators in the house?

If you want to know if you have an actual real-deal product, look for the manufacturer's mark:

Here's the top of the lower piece, can you tell what it is?

The bottom:

And for the grand finale...

That shot has the piece upside-down, just stand on your head to see how it will look. I'll wait while the blood rushes to your head and you pass out.