SomeGuyFromNYC

Member

- :

- '14.5 CX5 Grand Touring AWD w/ tech

Any updates?

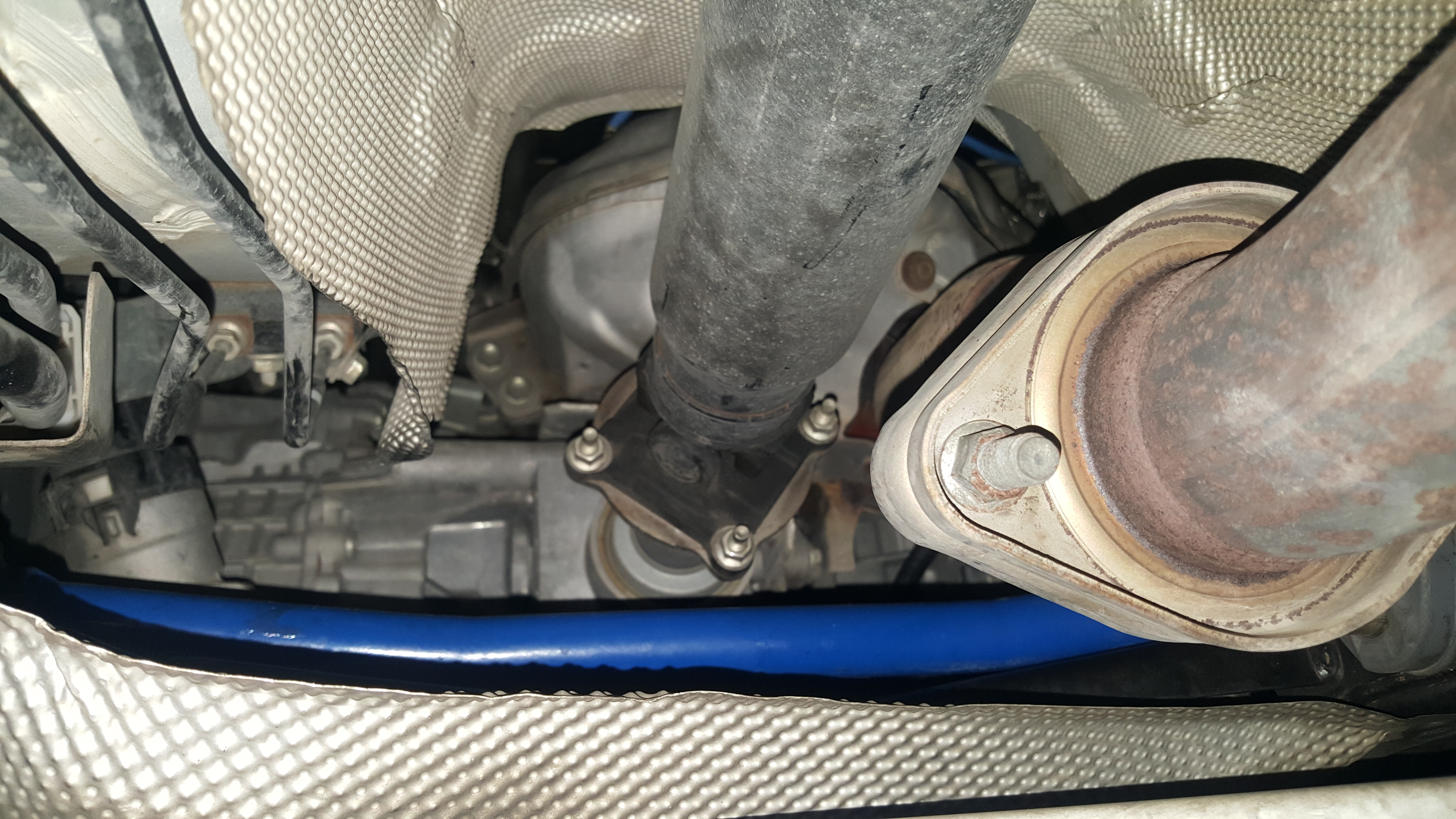

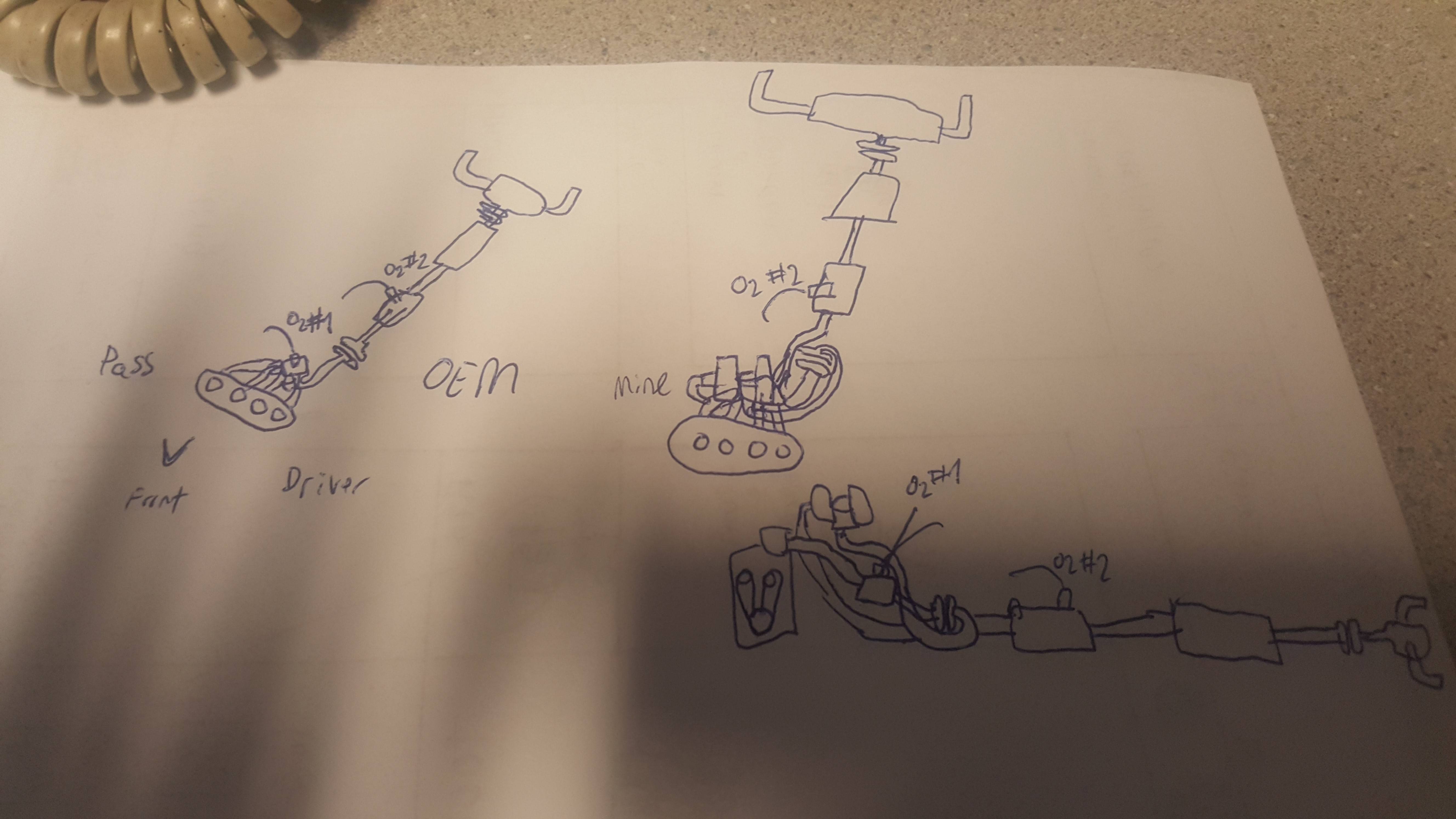

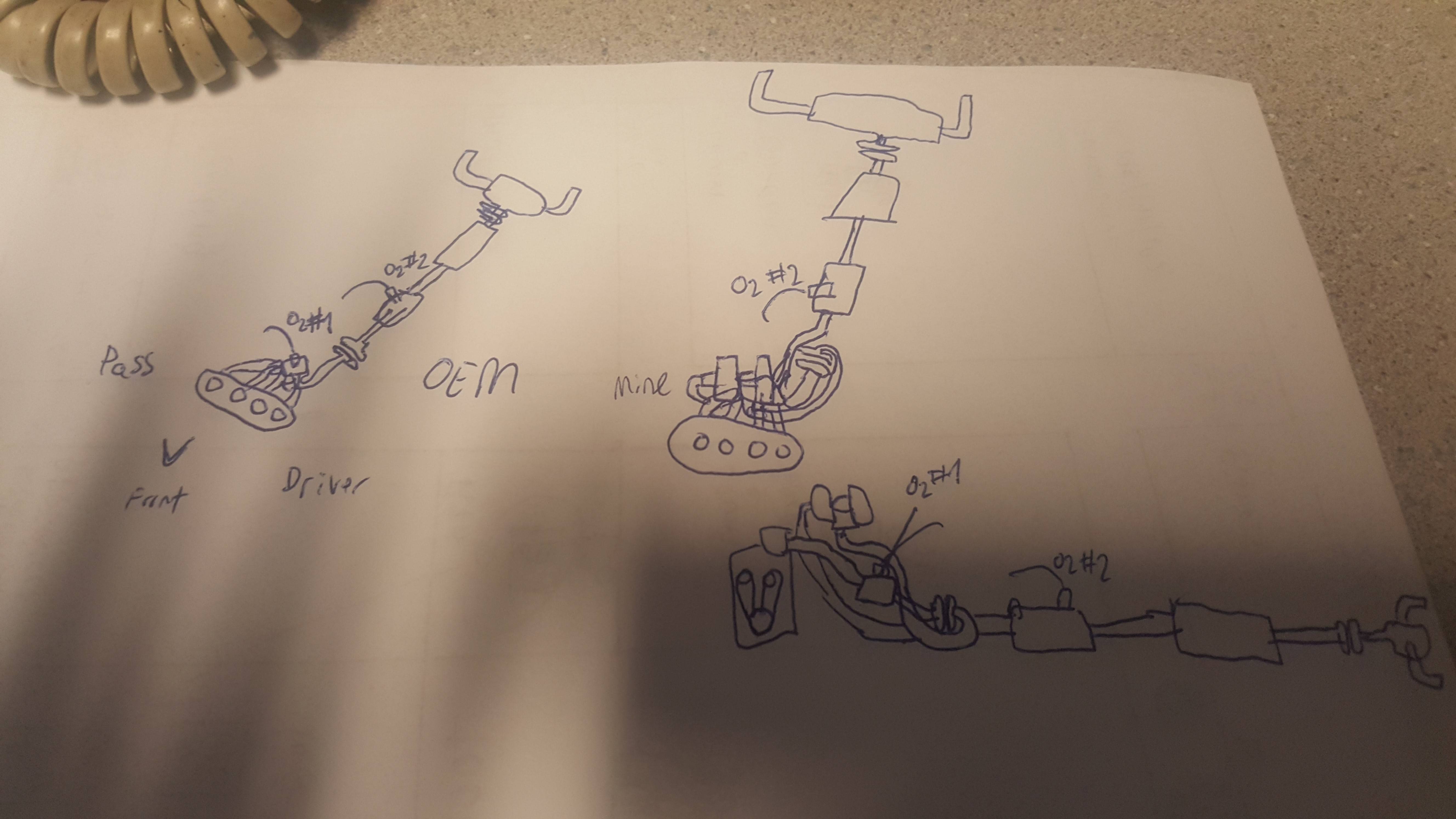

I've ordered a smaller turbo that can hopefully fit back here without having to be disassembled (like my current one). I'm building an up pipe, subie style. Basically an up pipe takes exhaust gas and routes it into the turbo. It off the manifold exit, up through the right side opening, and I will have the turbo sitting over the mani. I will use existing blot holes to assist in supporting it. The downpipe (turbo exhaust to car exhaust) will be coming off the left side, However even with that catch can moved, I'm not sure I can get a 2.5 pipe in there (using minimal length of smaller pipe, so through there I may have to use a 2" pipe. I was going to just build a new mid section since it's just a straight 2.5 with a flange, but I don't want to try to rebuild all the hangers. Once I'm satisfied with the turbo op I will just cut the original pipe enough to connect the downpipe into it with a vband clamp, or two bolt flange. All that stuff will be wrapped and any hoses foil taped if needed.

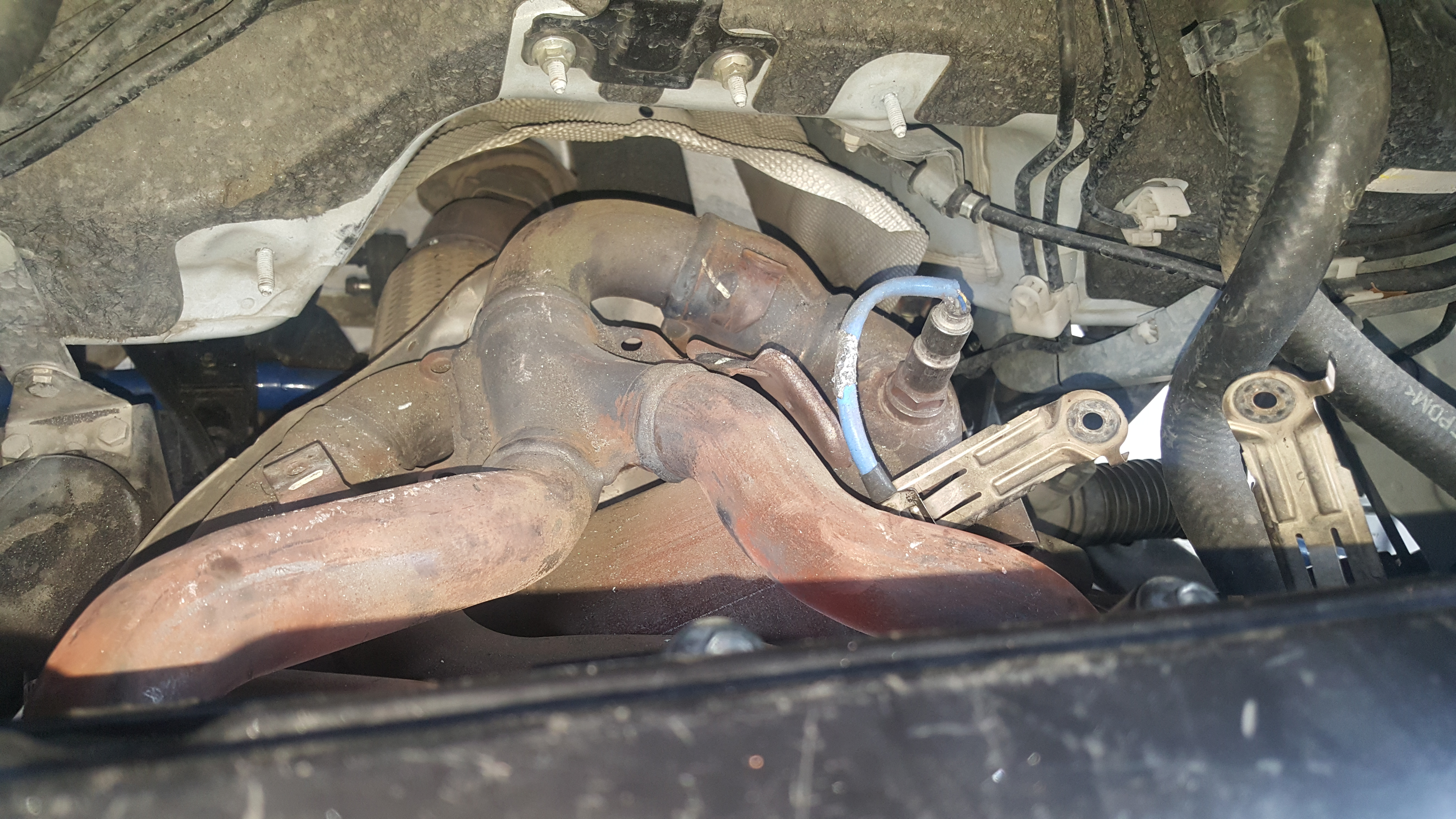

Cover removed from mani, opens up a good amount of space

A U shaped pipe will go left of the mani flange, just right of the steering shaft. It will accommodate a 2.5" pipe with room.

Space where the up pipe will pass. I may end up replacing those shaped heater hoses with regular type so I can reroute them away from the up pipe.

Space where I anticipate the DP going. from rough testing the 2.5 pipe would not fit in there. I may be able to use a 2.0 pipe or 2.25 just to transition that area. The other though, which I probably wouldn't bother with was using a 1.5" splitter and using two 1.5" pipes to collect back into the 2.5. But that seems like extra trial and error/fabricaton unless I encounter an issue with the smaller section. That little black thing is the catch can, and I can reposition the bracket to move it more towards the left.

I cut the mani cover up so that i could still bolt the pieces back on in order to remove it. Otherwise, you can't. Also I wasn't even going to try to remove the 02. sensor to get it out; for one it's like cemented in there, and two it's liable to be broken, but also there is like no working room to even loosen it. I covered the cut areas with foil tape just to kind of fill the gaps when I have it installed.

Oh there is defintely room for a top mount or bottom. The issue is getting a manifold, and if you have AWD the pain to remove it

I have the part's to try two different oil drain set ups, however I am currently exploring a more ideal mounting position (that also will let me keep my current ride height).

Chris can you explain a little bit more on what you did to the exhaust mani in order for turbo to fit. Like what did you do wielding and fitting wise. It seems like you added a split of where the mani ends and have pipe going to thr cat and pipe going to the turbo is this correct? Also where did you get your turbo from.

Sent from my XT1254 using Tapatalk

Interesting so it still goes through the cat. So the exhaust exits the mani goes to the turbo. What happens after that??I didn't do anything to the exhaust manifold. I removed the top part of the heat shield by cutting it into 3 sections so I could pull it out from above after unbolting it. I am simply building a pipe coming off the manifold exit to the turbo instead of it leading into the catback exhaust system. I will build a downpipe off the passenger side of the the turbo and intercept the oem midpipe. I repurposed one of the shield bolt holes into a bracket mount.

Been away from the site for a couple years and just chugging along with a whopping 9,800 miles in the last 3 years.Time for my first tire rotation.

Chris the last time I was lurking you had a flashed ECU that returned a 0-60 time of 7 seconds flat. Now a turbo is in your sights, so what are you trying to get, in the high 5 second range? Can the tranny handle it? Have you found a shift kit?

I didn't think the motor's high compression had enough head room for the extra 5 psi of boost, has someone else boosted their's too?

Glad to see your enjoying your ride!