so i installed it tonight. that sucked. i spent the majority of the time messing around with the engine mount itself, whether it was making sure that the engine was supported sufficiently, getting the nuts off (pretty much stripped the stock nuts), or if it was getting my hands in the crevice to work on getting the bolts in. overall, it sucked.

but i got it on.

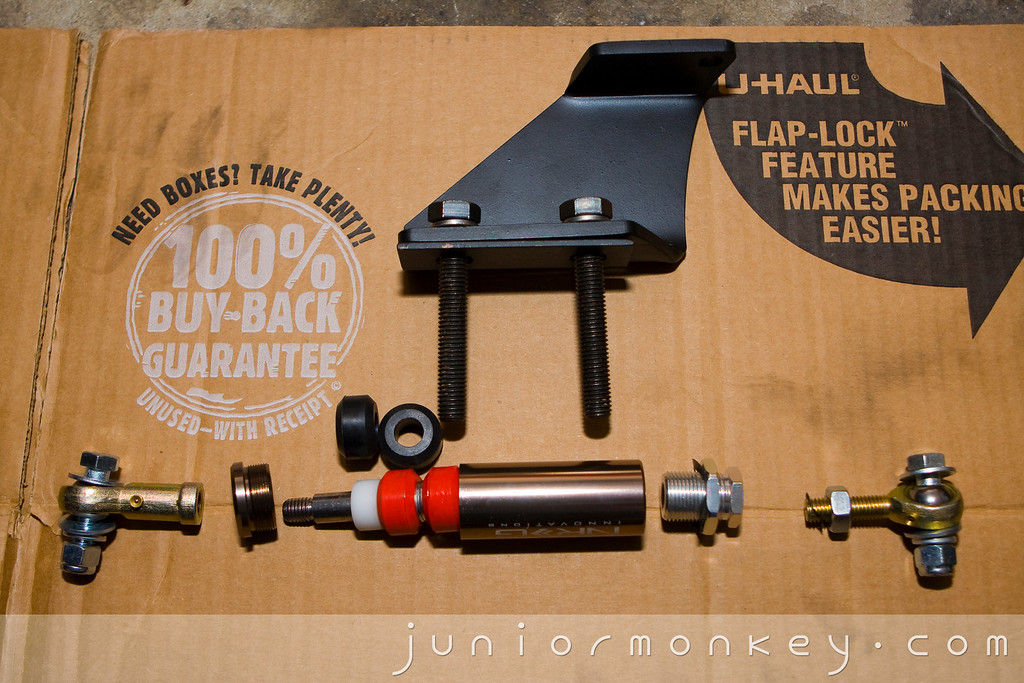

i took the damper apart just to make sure that what bani was saying and what i was thinking was right. and the bushings are exactly the same, except for the color.

i ended up putting the damper underneath both the tower bracket and the engine bracket, as opposed to captain krm p5's below the tower bracket and on top of the engine bracket orientation. i'm not sure what all captain has done under his engine, but without the faux plastic spacers, the damper was still pretty level. this was also more out of the way of the oil cap. it's pretty close to the hoses, but there's no contact whatsoever, and i can't imagine any contact under movement.

with the damper positioned this way, it still turned out pretty level, and everything seems to have the proper clearance.

so i suggest to captain that he go back and remove those plastic spacers (which are really replacement bushings) before your engine rattles off the mounts.

oh, and thanks for the heads up on the bushings, bani.