You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum lug nut warning

- Thread starter dps03

- Start date

I've only had a couple different sets of after-market rims, previously (on other models of cars than the one I driven now).

1. A lower-end aluminum set from TireRack (TSW, perhaps) -- on those, I just used a standard steel lug nut set.

2. A high-end Enkei RP-F1 flow/forged aluminum set -- used with the McGard SplineDrive hardened-steel lug nuts.

Myself, I don't think I'd want to use aluminum lug nuts. Bad place to have reduced strength, increased risk of brittleness, even as enticing as a minor bit of weight reduction might be.

1. A lower-end aluminum set from TireRack (TSW, perhaps) -- on those, I just used a standard steel lug nut set.

2. A high-end Enkei RP-F1 flow/forged aluminum set -- used with the McGard SplineDrive hardened-steel lug nuts.

Myself, I don't think I'd want to use aluminum lug nuts. Bad place to have reduced strength, increased risk of brittleness, even as enticing as a minor bit of weight reduction might be.

- :

- Mazda CX-9 Signature

I am not accusing you of anything. Just stating I personally have a hard time processing this ordeal. The wreckage looks very clean and free of salt and rust so for them to seize up like that in 2 months is difficult to fathom.Two months.

Jack Rabbit

Banned

- :

- 18 Mazda CX5 AW

Yeah they assumed you had a tire shop put them on and that their answer would satisfy a gullible customer.It gets worse...

Just heard back from their customer service rep. They said that their "hardware experts have stated that the lugs got cross threaded and an impact wrench was used when starting out."

Well, for the record, I hand tightened them, then torqued them to spec by hand using a torque wrench set to 90lbs.

I made them a video of one of the broken halves of a lug nut showing it spin easily on and off to prove that it was not cross threaded.

Will see what they have to say about that.

I'm really not out for anything other than for them to warn folks about these and to hopefully stop sending them out.

Any expert knows that an aluminum nut on a steel stud will corrode and freeze.

Jack Rabbit

Banned

- :

- 18 Mazda CX5 AW

As long as water is present, aluminum and steel is very corrosive when mated. I've seen this occur on houses within 1 month time where steel met aluminum as contractor was attempting to save money.I am not accusing you of anything. Just stating I personally have a hard time processing this ordeal. The wreckage looks very clean and free of salt and rust so for them to seize up like that in 2 months is difficult to fathom.

Aluminum to aluminum always. Steel to steel stays strong.

Only reason steel lugs dont corrode aluminum alloy rims is both are painted including contact points. However the threads are bare and thus corrosive. Steel lugs for steel studs.

Alot of times thas corrosion is almost invisible as it is silver white. Check an aluminum pool deck with steel fasteners and is hard to see.

Last edited:

I am not accusing you of anything. Just stating I personally have a hard time processing this ordeal. The wreckage looks very clean and free of salt and rust so for them to seize up like that in 2 months is difficult to fathom.

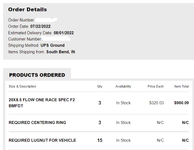

Here is proof as to when I bought the things...it happened in two months.

Note that I already had one wheel/tire (I made sure the thing fit front and back before I bought the other three).

Here is a snippet showing they were not crossthreaded.

Attachments

Similar threads

- Replies

- 5

- Views

- 2K