You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

magnumP5's RX-7 Build Thread

- Thread starter magnumP5

- Start date

- :

- 2001 Mazda MP3

then would building a 20B be like building a big mac?building a rotary is kind of like making a sandwich

mymmeryloss

Member

- :

- 13bT Mazda B2600i

No a 20b is like a perfect club sandwich...

PrinceValorum

Member

- :

- 95 626 FS, 89 Toyota Derux 4x4

No a 20b is like a perfect club sandwich...

And this is a 4 rotor!

All this sandwich discussion is making me hungry!

The TII oil pump arrived, but there's no point in taking a picture because it looks exactly like my stock oil pump. I just about finished cleaning parts last Friday so it looks like I'll finally be able to box up everything to be balanced and ship it out next week. The only parts not cleaned are the intermediate housings because I ran out of brake cleaner. I'm nervous about cleaning them because they're mostly bare cast iron and will quickly rust out if I'm not careful. I'd put them in the oven but our oven is too nice $1300 worth of parts were shipped yesterday so they should be arriving tomorrow or Saturday. Then I get to go through it all to make sure I got everything. I've also finished all my other projects around the house so I should be able to get back to working on the RX-7 in the coming weeks, yay!

$1300 worth of parts were shipped yesterday so they should be arriving tomorrow or Saturday. Then I get to go through it all to make sure I got everything. I've also finished all my other projects around the house so I should be able to get back to working on the RX-7 in the coming weeks, yay!

The TII oil pump arrived, but there's no point in taking a picture because it looks exactly like my stock oil pump. I just about finished cleaning parts last Friday so it looks like I'll finally be able to box up everything to be balanced and ship it out next week. The only parts not cleaned are the intermediate housings because I ran out of brake cleaner. I'm nervous about cleaning them because they're mostly bare cast iron and will quickly rust out if I'm not careful. I'd put them in the oven but our oven is too nice

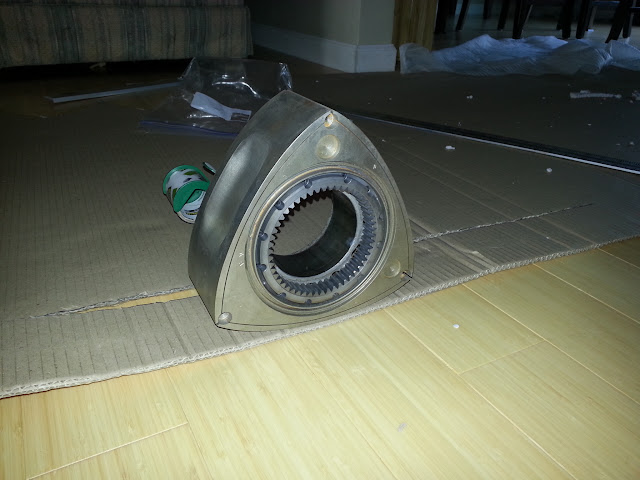

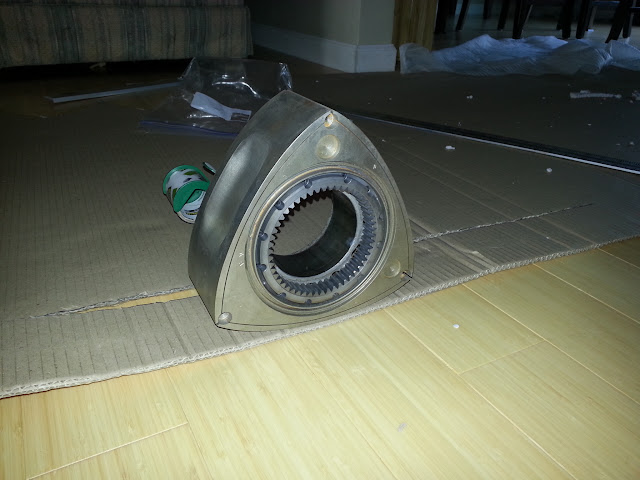

$1300 worth of parts came in on Friday. Well, most of $1300 worth of parts. After taking a quick inventory I noticed I was missing 5 side seals, 1 corner seal spring, and a dipstick. No worries as all is straigtened out and I should have those parts by this Friday. Parts for balancing are being ordered/shipped today. The one question I forgot to ask was turnaround time... I thought Evan would get a kick out of this:

A paranoid's guide to preparing rotors for shipping:

1. Start with clean rotor:

2. Wrap with 1/4" cardboard:

3. Wrap with 1/4" foam:

This was my first attempt. The foam kept breaking on me. The next attempt was much better (see below).

4. Wrap with 1/4" cardboard (again!):

After the pictures above I wrapped it in that thin, flexible foam sheet stuff. In the end I added about 1" worth of packaging/padding around the rotor, and they're still going to go into a well-packed box. Any ding or dent can very easily cost me a $500 part.

The plan is to resume working on the car (finish wiring) this weekend when the temperature drops.

A paranoid's guide to preparing rotors for shipping:

1. Start with clean rotor:

2. Wrap with 1/4" cardboard:

3. Wrap with 1/4" foam:

This was my first attempt. The foam kept breaking on me. The next attempt was much better (see below).

4. Wrap with 1/4" cardboard (again!):

After the pictures above I wrapped it in that thin, flexible foam sheet stuff. In the end I added about 1" worth of packaging/padding around the rotor, and they're still going to go into a well-packed box. Any ding or dent can very easily cost me a $500 part.

The plan is to resume working on the car (finish wiring) this weekend when the temperature drops.

2.0t03speed

Member

- :

- 08.5 CWP Speed 3

looks good man whens the next time you're going to be down in virginia beach? Since i moved i'm only about 5 mins from your parents place now.

PrinceValorum

Member

- :

- 95 626 FS, 89 Toyota Derux 4x4

That's awesome, I'd be thrilled to receive a package that well packed!

mymmeryloss

Member

- :

- 13bT Mazda B2600i

Excited for updates! Damn you winter!

LOL, believe it or not I took it to FedEx and when I said they were fragile they wrapped 'em up even more with bubble wrap and slapped like ten "Fragile" and "This side up" stickers on the box. Those guys don't mess around. This is why FedEx > UPS >> USPS. BTW, most declared value of any package I've ever shipped ($1500!).That's awesome, I'd be thrilled to receive a package that well packed!

Not sure yet. I was staring at the engine bay earlier this week (as I often do) and remembered all the vacuum lines and wiring I've already got wrapped up. It wouldn't be too hard to remove the vaccum lines and cover the wiring but it would be time consuming. I think once I get all the wiring completed and the dummy engine out I'll give everything a good cleaning and go from there.Did you decide on a color for your engine bay?

I actually think I get more stuff done in the Spring/Fall than any other time. Hopefully I'll get to make up for getting next to nothing done this Summer. The tentative plan is to get everything wrapped up this Fall/early Winter, build the engine early next year, and start up/tune next Spring.Excited for updates! Damn you winter!

It's hard to say how much I've spent. For my sanity I've tried to avoid adding everything up. Including the car I'll probably be around $10k when all is said and done. The important thing to note is I got my FC for $3k and that was still probably too much. With an FD you're looking at $15k-$18k easily for a base '93 with manual transmission and tan interior. It only goes up from there.Sub'in and great work so far, wish this was an FD R2 , best RX7 body.

Whats the total expenses so far if you don't mind ? I was thinking of doing the same work either on a FD R2 or 240sx/silvia .. they are pretty much best RWD of their times.

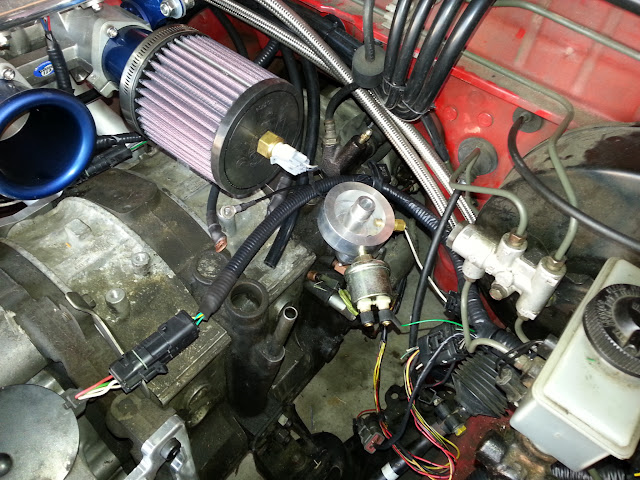

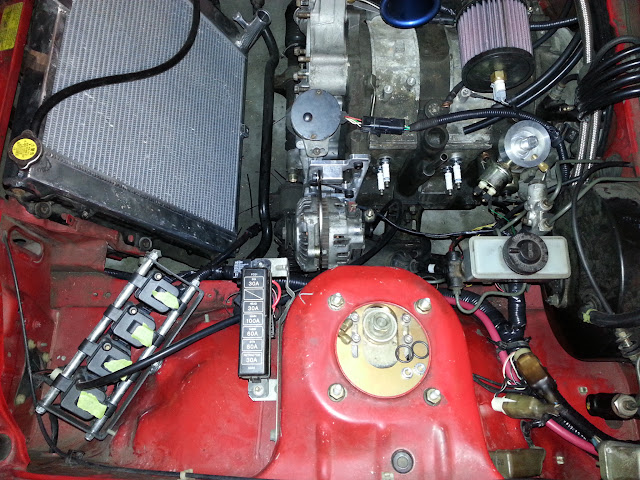

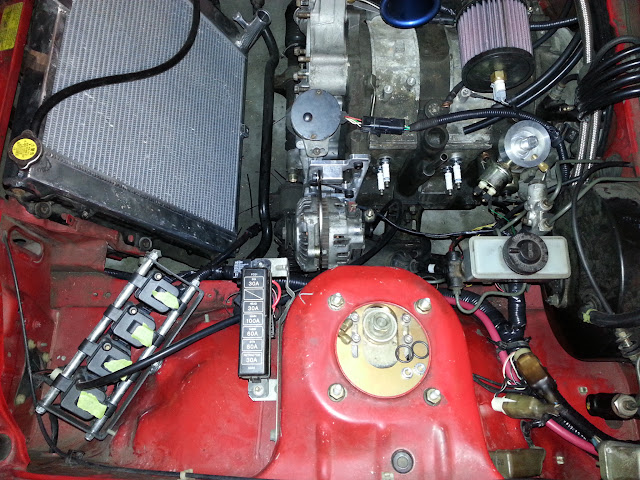

I actually worked on the car this weekend! I spent a good six hours or so on the wiring in the engine bay. Except for the alternator and starter power wires everything is connected. I have about another 12" of wire remaining that needs to be covered on the main branch but I ran out of electrical tape. I also need to shorten the wires that run to the transmission about 6" but I think I'll do that with the engine out. Here's some shots of how everything looks right now:

I'm not super happy with how the loom turned out but at this point I'm not sure there is much I can do short of redoing everything, which I DEFINITELY don't want to do. This corrugated loom stuff isn't the easiest to work with. I originally wanted to use that mesh stuff everyone seems to be using nowadays but I wasn't convinced it would protect the wires enough. Maybe everything'll look better when the engine bay is cleaned...

Lastly, here's a picture of the rebuild parts sans housings and rotating assembly.

If you include the ceramic apex seals (near center in clear box) there's over $2000 worth of parts in this picture!

I totally agree with you on the loom and mesh stuff (Tech flex, I think it's called). The loom is easy to work with but doesn't look very fancy. But it seems like it will hold up much better and protect the wiring better than the tech-flex. But function over fashion, especially if you would have to rewire something. No thank you. haha. Looking good though, buddy.

roy obanion

Member

- :

- 02 p5, 95 miata

Looking good, buddy!

More work done!

The main harness is completed. It still looks pretty ugly but as long as it keeps the wires dry/cool it'll do for now. All that's left are alternator power wires, the starter power cable, the spark plug wires, and trimming the transmission harness once the dummy engine's out.

This area was a PITA:

I put the alternator and some spark plugs in to get an idea of how to route the spark plug wires:

I'm thinking 90 degree boots at the coils then the wires run next to the fuse box, over the alternator, and down to the plugs with straight boots. This should keep them from the main harness and any wires it comes near will be crossed at 90 degree angles.

Tonight I'm hoping to get the alternator wires finished and take the measurements for the spark plug wires so they can be ordered tomorrow.

The main harness is completed. It still looks pretty ugly but as long as it keeps the wires dry/cool it'll do for now. All that's left are alternator power wires, the starter power cable, the spark plug wires, and trimming the transmission harness once the dummy engine's out.

This area was a PITA:

I put the alternator and some spark plugs in to get an idea of how to route the spark plug wires:

I'm thinking 90 degree boots at the coils then the wires run next to the fuse box, over the alternator, and down to the plugs with straight boots. This should keep them from the main harness and any wires it comes near will be crossed at 90 degree angles.

Tonight I'm hoping to get the alternator wires finished and take the measurements for the spark plug wires so they can be ordered tomorrow.

Similar threads

- Replies

- 0

- Views

- 2K