You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LankyKiwi's Rally-flavored SP20

- Thread starter LankyKiwi

- Start date

JazzySP20

Madaz

- :

- AUSTRALIA

- :

- BJII Astina SP20

I'd prefer the cable over the electric, they last way longer.

You're mechanically conected to the flapper, you know when it needs oil, it gets harder to move.

Electric motors wear out, dry out and seize up with crap.

18 years and not a single issue with the automatic climate control in my BJII SP20. I know the original owner and I am the second owner. Maybe it's just the US spec cars that are riddled with electrical issues?? (wink) Seriously though, reading about the electrical issues you guys in the US and Canada have with these cars, makes me think that the JDM/Australia cars are completely different altogether. (dunno)

Where were the North American spec BJ's built?

I love it that I can leave the middle and right dials on Auto 95% of the time and only have to adjust the left temperature dial to suit my needs. The Auto CC takes care of everything! (yes)

18 years and not a single issue with the automatic climate control in my BJII SP20.

I was speaking generally about all cars.

My electric fresh/recirculate switch is working fine.

But if it craps out I'm sure it would be a lot more money to get fixed, especially if you have to take it to the shop like how most people do.

There's a lot more salt, rust, dirt and climate changes here where I live. -30 C in the winter and +35C in the summer with 95% humidity.

Two years ago a guy went through our local Tim Horton's coffee shop drive through for a coffee.

His drivers side power window wasn't working so he pulled ahead a bit to reach around his door to grab the coffee and somehow hit the gas and pinned his head between the car and the side of the building and was killed.

If that guy had old school mechanical wind up windows, he'd still be alive today.

Where were the North American spec BJ's built?

I remember reading that all North American Protege5's were 100% built and assembled in Japan.

I remember too that in Japan the cars are required by law to be built using 100% recycled metal and it's reaĺly dificult to get all the impurities out of the metal making the metal way more inclined to rust.

All the cars around here are rusty but my Mazda is exceptionally good at it.

Having had 2 rusty English cars and 1 rusty van, pics like that give me nightmares!

Got the car aligned today, it was out a little on the passengers side from when I bent the wheels, which makes sense. It's great now, nice and neutral in the corners and the slight brake shudder seems to have been fixed too. Gotta love local mechanics who know what they're doing!

It looks like the rear engine mount is toast, the gearbox casing is sitting real close to the crossmember and might actually be hitting it. Luckily I've got a spare ready to go filled with urethane but it's not a job I'm looking forward too!

Got the car aligned today, it was out a little on the passengers side from when I bent the wheels, which makes sense. It's great now, nice and neutral in the corners and the slight brake shudder seems to have been fixed too. Gotta love local mechanics who know what they're doing!

It looks like the rear engine mount is toast, the gearbox casing is sitting real close to the crossmember and might actually be hitting it. Luckily I've got a spare ready to go filled with urethane but it's not a job I'm looking forward too!

Riot_Polizei

Comp Engineering Student

- :

- 2002 Mazda Protege5

Jeez, good luck with that rear mount. Of all the readings I've done on it, you either gotta be a contortionist or a masochist lol. Does not looke like a fun job.

Hmmmmmmmmm...

Might need a bit of tweaking to fit!

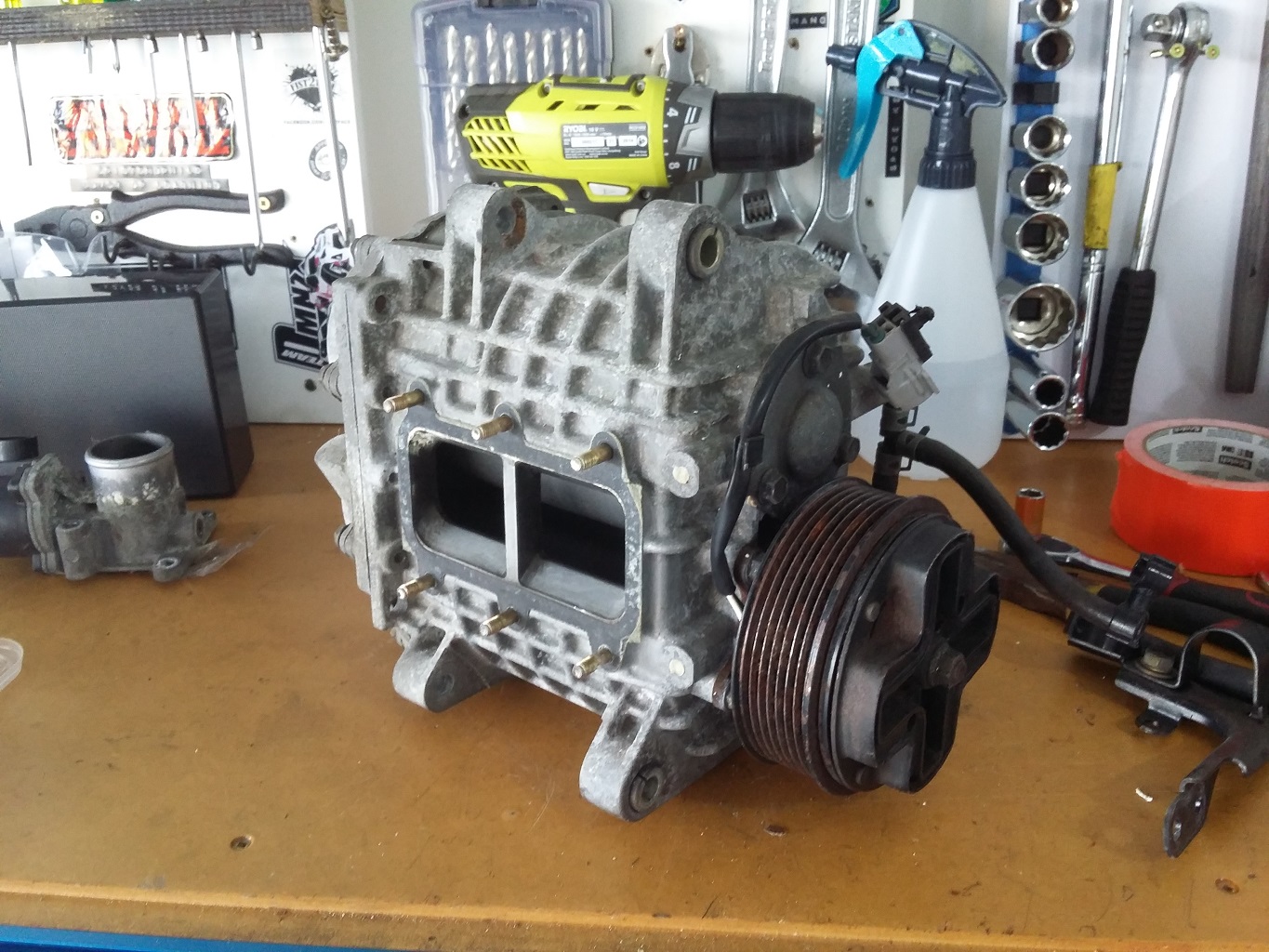

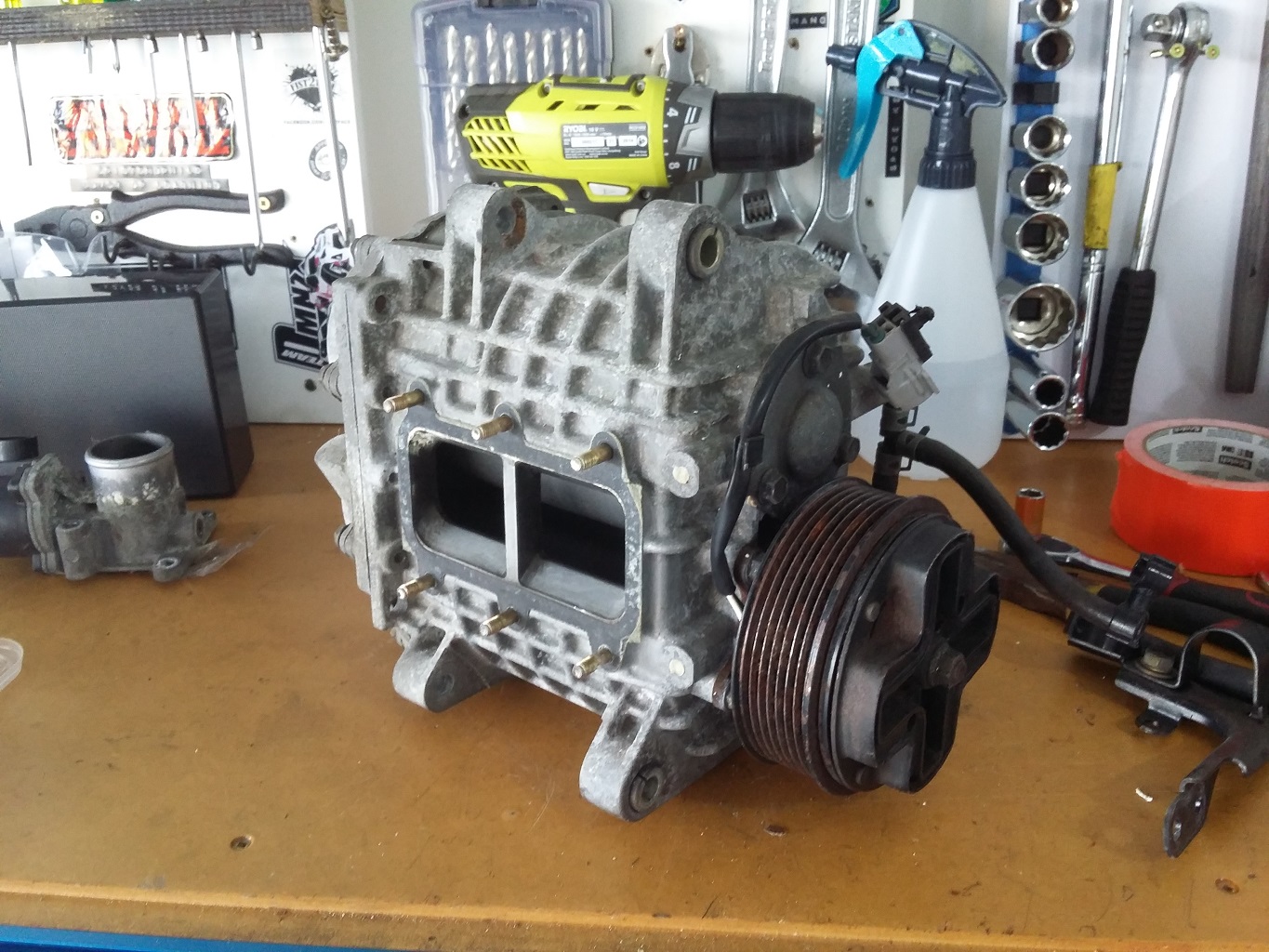

Pulled the trigger on a SC14 supercharger from a Toyota Estima people mover, they've got a good reputation and are about the right size for the engine. Plus it's got a switchable pully to turn it on and off!

It doesn't look as scary with all the intake pipes removed;

It's going to be a fun challenge sorting out mounts, belts, wiring and everything else for this thing!

Might need a bit of tweaking to fit!

Pulled the trigger on a SC14 supercharger from a Toyota Estima people mover, they've got a good reputation and are about the right size for the engine. Plus it's got a switchable pully to turn it on and off!

It doesn't look as scary with all the intake pipes removed;

It's going to be a fun challenge sorting out mounts, belts, wiring and everything else for this thing!

JazzySP20

Madaz

- :

- AUSTRALIA

- :

- BJII Astina SP20

You'll prob have to loose most of the A/C system (compressor, condenser, dryer, etc), and make a custom half size radiator mounted on the right side of the engine bay to make room for it to fit.

And these SC's are very noisy if not intercooled.

What are your plans on tuning the ECU to suit?

And these SC's are very noisy if not intercooled.

What are your plans on tuning the ECU to suit?

Thanks guys, yep the AC will go, I never use it anyways so removing it provides a lot more room to play with, and cuts out a bit of weight too

This is a really, really long term project, I'm picking up stuff as it comes up for sale and researching just exactly what needs to be done. Some stuff I'm not 100% on yet, like the intercooler and ECU setup (Megasquirt looks like a good option at the moment) any input, feedback, ideas etc will be much appreciated!

Before I rip in to building stuff I need to sort out a shed space to do it all in, and a daily driver so I can focus on pulling this one apart without jeopardising my ability to get to work so it's going to be a long while before anything happens with this particular project.

so it's going to be a long while before anything happens with this particular project.

This is a really, really long term project, I'm picking up stuff as it comes up for sale and researching just exactly what needs to be done. Some stuff I'm not 100% on yet, like the intercooler and ECU setup (Megasquirt looks like a good option at the moment) any input, feedback, ideas etc will be much appreciated!

Before I rip in to building stuff I need to sort out a shed space to do it all in, and a daily driver so I can focus on pulling this one apart without jeopardising my ability to get to work

Back to slightly less fun, maintenance stuff here;

Those with AWR rear bars, are your end link rosejoints rattling away? Mine seem to have worn enough that it clunks and rattles all the time the bolts are tight, the rubber donuts are in ok condition, I can grab the sway bar and move it a few mms up and down at each end. Hopefully I can find some imperial threaded rose joints here if I need to replace them, does anyone have the size/Thread details?

the bolts are tight, the rubber donuts are in ok condition, I can grab the sway bar and move it a few mms up and down at each end. Hopefully I can find some imperial threaded rose joints here if I need to replace them, does anyone have the size/Thread details?

Those with AWR rear bars, are your end link rosejoints rattling away? Mine seem to have worn enough that it clunks and rattles all the time

Riot_Polizei

Comp Engineering Student

- :

- 2002 Mazda Protege5

Dang dude, this is going to be one hell of an undertaking. I look forward to any progress you make!

Unfortunately, I haven't the foggiest about AWR's swaybar + adjustable endlinks. However, supposedly you can grab replacement adjustable endlinks from a Mazda dealer or from Mazda Motorsports's parts section (must be a verified member!)

Unfortunately, I haven't the foggiest about AWR's swaybar + adjustable endlinks. However, supposedly you can grab replacement adjustable endlinks from a Mazda dealer or from Mazda Motorsports's parts section (must be a verified member!)

Yep, the AWR endlnks are noisy for sure. Never had a problem, but very annoying and unnerving for some passengers.

I dealt with it for awhile and started messing around to see what would keep them quiet. What worked for me was to not use any of the hardware from AWR lol. I use only the endlinks attached with a nyloc nut. No o-rings, no conical bushings, no washers, nothing. Just the links themselves. Haven't had any issues and their quiet. Don't care if it's right or wrong. Works fine for years now. However, I had the rear RB MSP rear bar so I could do this for the top and bottom links. For the AWR bar clamp thingy, which I never liked, you can't do this unless you have some spacers to take up the extra room you'll have if removing the AWR o-rings, conical bushings etc.

Right now I have no rear sway bar but when my front BC endlinks died, I installed my old beat up AWR links way. No issues, for years.

I dealt with it for awhile and started messing around to see what would keep them quiet. What worked for me was to not use any of the hardware from AWR lol. I use only the endlinks attached with a nyloc nut. No o-rings, no conical bushings, no washers, nothing. Just the links themselves. Haven't had any issues and their quiet. Don't care if it's right or wrong. Works fine for years now. However, I had the rear RB MSP rear bar so I could do this for the top and bottom links. For the AWR bar clamp thingy, which I never liked, you can't do this unless you have some spacers to take up the extra room you'll have if removing the AWR o-rings, conical bushings etc.

Right now I have no rear sway bar but when my front BC endlinks died, I installed my old beat up AWR links way. No issues, for years.

The local parts store had a 30% off sale so I snagged some nolathane trailing arm bushes for the rear and some front sway bar mounts ($30!) to swap in at some point

Still on the look out for supercharger parts, need a wastegate, blow off valve and a small intercooler before I can start doing anything serious, but it's getting closer!

Still on the look out for supercharger parts, need a wastegate, blow off valve and a small intercooler before I can start doing anything serious, but it's getting closer!

Similar threads

- Replies

- 0

- Views

- 7K