SayNoToPistons

Wheels, not rims...

- :

- CX-5 GT AWD w/ Tech, RX-8 GT 6spd w/ 'goodies'

For the front it is relatively hard to jack up from the pinch welds using a non-scissor jack without the notch. Not only that, it is also hard to put on a jackstand on the pick weld after jacking the car up from where ever you did. Got a few tips for those having trouble.

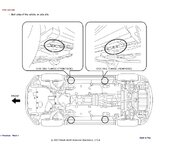

Use the solid cast steel mounts for the lower control arms of the front suspension as a jack point. These are high strength and solid mounts which are directly connected to the sub-frame and unibody of the car. Perfect for using as a jack point. I like to use a folded rag between the jack top and the mount itself to provide better grip and a large contact area.

Once the car is jacked, use the pinch weld as the jack stand point. I prefer the pin type jack stands as I have seen and heard of notch type jacks stands slip and fail if not properly secured. The top of the jack stand that is most suitable is an almost flat V shape which allows the pinch weld to sit properly in the groove. Like with the jack, I like to put a thick rag in between the pinch weld and the jack top.

For the rear, make sure the front is either on jack stands or the wheels are chocked. Granted the front wheels are somewhat locked if you have an AT in Park (or in gear if MT), there is still allowable movement. Use the rear differential case as a jack point. It is another high strength cast steel casing that is directly mounted to the subframe. It is also right smack in the center of the car, so no balance issues. Once it is jacked, follow the same procedure for the pinch weld jack points.

Use the solid cast steel mounts for the lower control arms of the front suspension as a jack point. These are high strength and solid mounts which are directly connected to the sub-frame and unibody of the car. Perfect for using as a jack point. I like to use a folded rag between the jack top and the mount itself to provide better grip and a large contact area.

Once the car is jacked, use the pinch weld as the jack stand point. I prefer the pin type jack stands as I have seen and heard of notch type jacks stands slip and fail if not properly secured. The top of the jack stand that is most suitable is an almost flat V shape which allows the pinch weld to sit properly in the groove. Like with the jack, I like to put a thick rag in between the pinch weld and the jack top.

For the rear, make sure the front is either on jack stands or the wheels are chocked. Granted the front wheels are somewhat locked if you have an AT in Park (or in gear if MT), there is still allowable movement. Use the rear differential case as a jack point. It is another high strength cast steel casing that is directly mounted to the subframe. It is also right smack in the center of the car, so no balance issues. Once it is jacked, follow the same procedure for the pinch weld jack points.

Last edited: