Forced_Firebird

Member

My name is John and I am an addict...

...must resist the urge to turbo everything.

Intercooler...

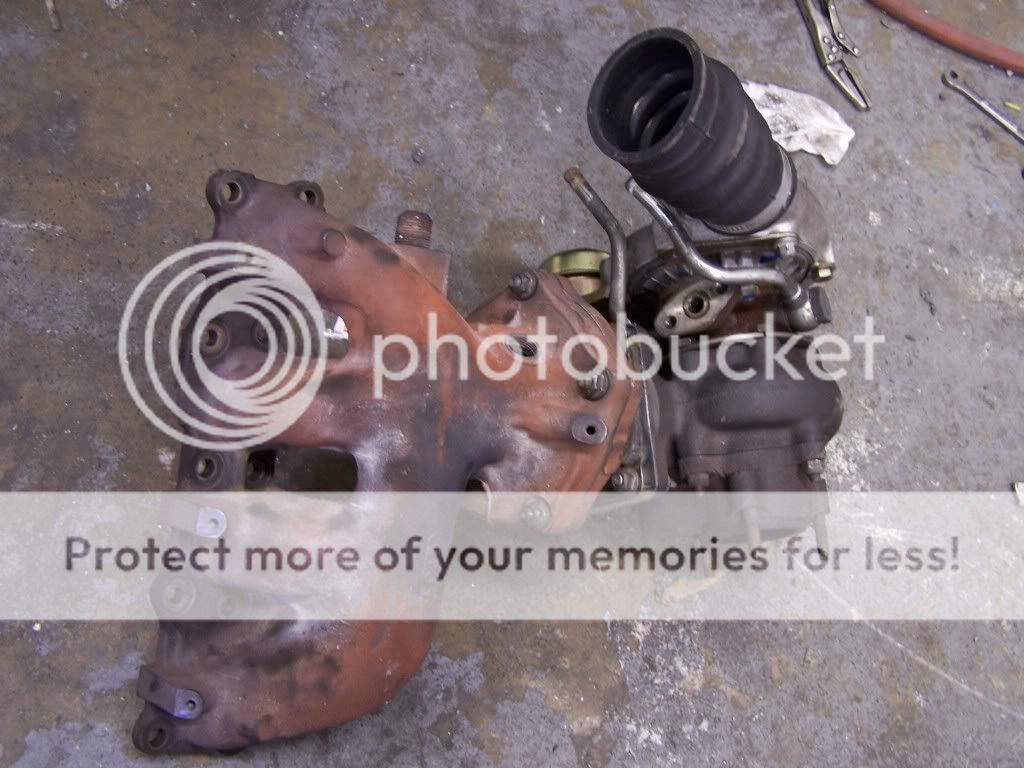

Turned the cat into a turbo adapter...

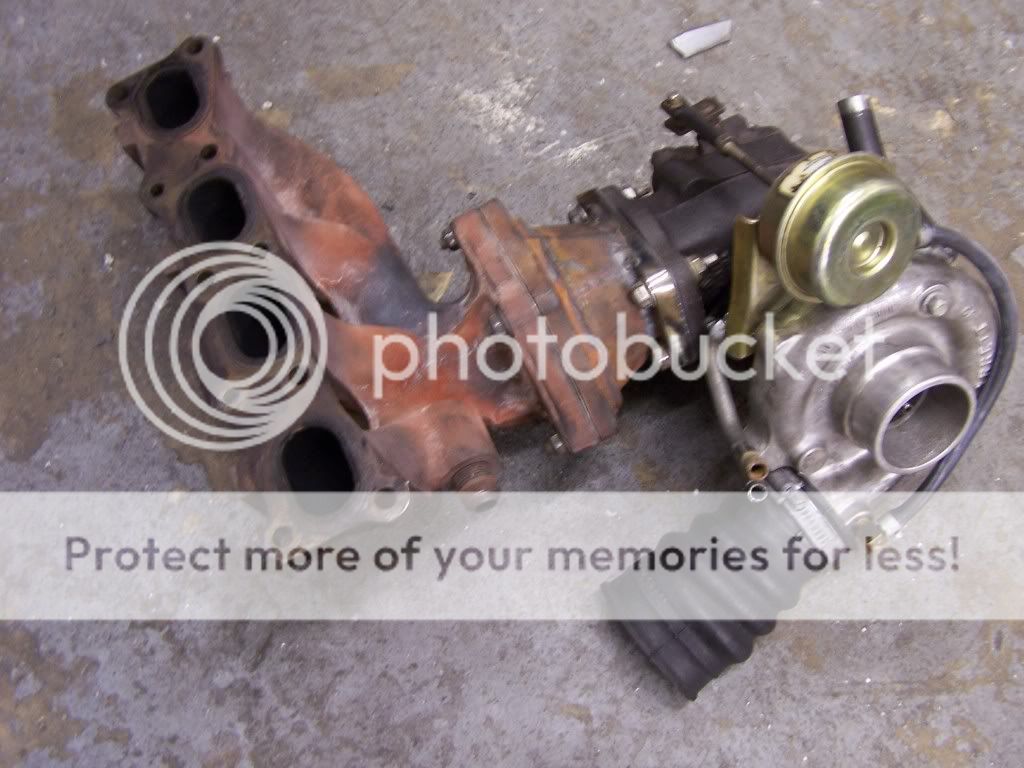

Mounted to the manifold, cheap junkyard turbo...

Mounted...

Used the junkyard oil drain and made it work...

Cut the bumper to clear the I/C...

And the cold pipes (removed the washer fluid res)...

We are about 10 hrs into the project. Still have to weld the oil dran pot in the pan and get the turbo some coolant, and get the wastegate situation figured out.

Using a FMU for now to get it running/driving and find the weak spot (tranny? car has 120k miles), then the Greddy eManage is going on as well as a BOV.

Hope you enjoyed the pics.

...must resist the urge to turbo everything.

Intercooler...

Turned the cat into a turbo adapter...

Mounted to the manifold, cheap junkyard turbo...

Mounted...

Used the junkyard oil drain and made it work...

Cut the bumper to clear the I/C...

And the cold pipes (removed the washer fluid res)...

We are about 10 hrs into the project. Still have to weld the oil dran pot in the pan and get the turbo some coolant, and get the wastegate situation figured out.

Using a FMU for now to get it running/driving and find the weak spot (tranny? car has 120k miles), then the Greddy eManage is going on as well as a BOV.

Hope you enjoyed the pics.