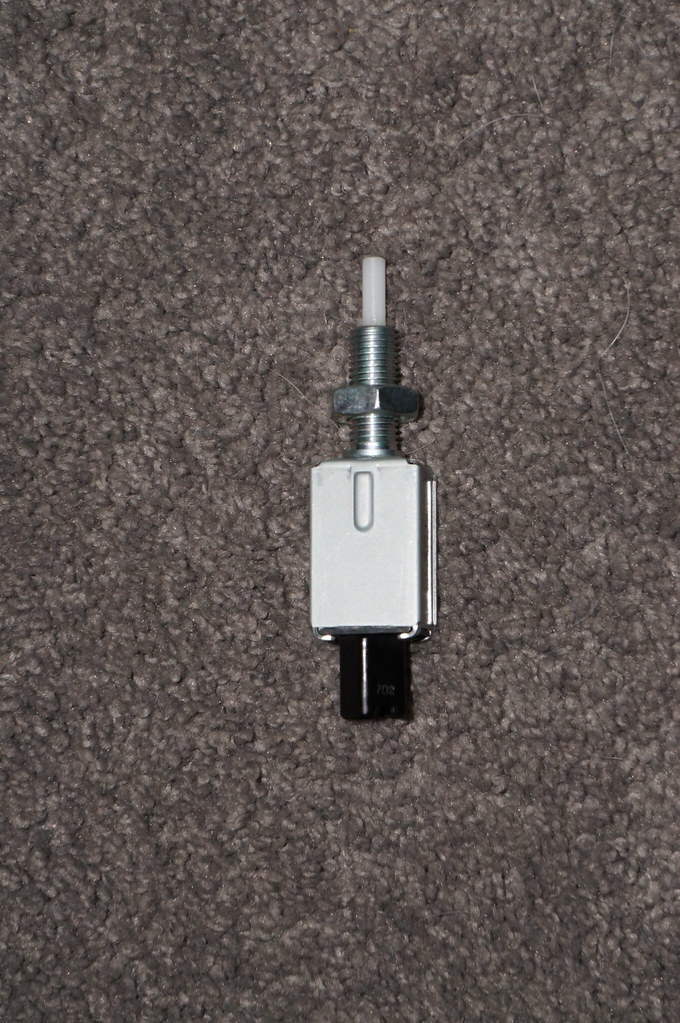

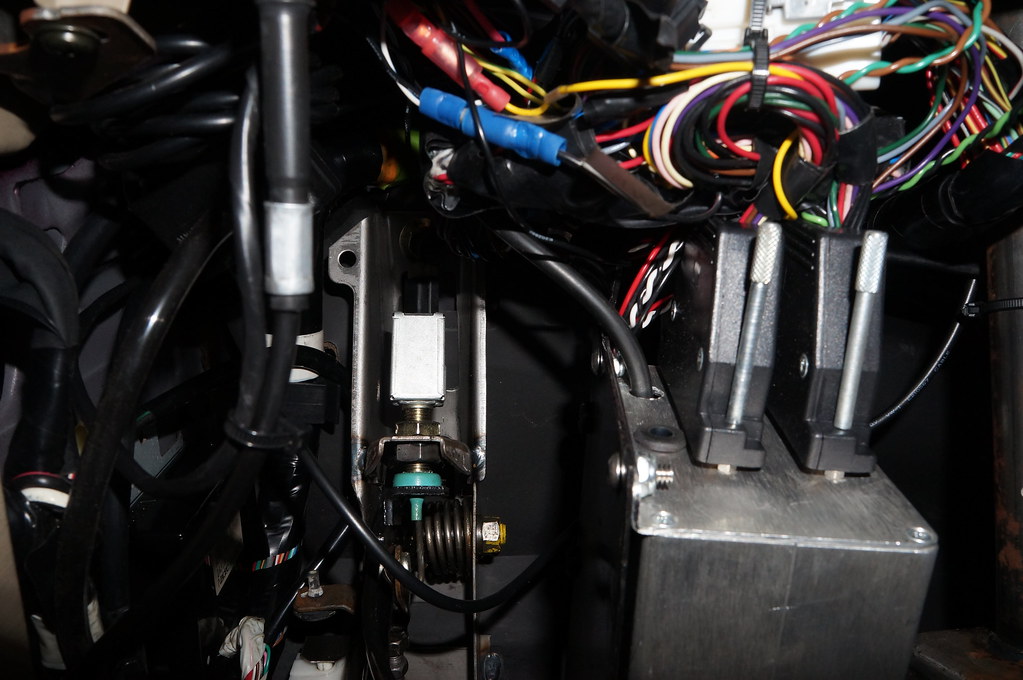

Last week I started to put the trans back in but as I jacked it up into position I remembered that I'd taken a small shower when we PULLED the bad transmission out because in so doing we had cracked the little coolant nipple cap on the back of the head. Since that would have been an immediate failure upon firing the engine up, and about a thousand times easier to do with the transmission out, I hit up one of the local Mazda dealership and picked up a new one.

The spare transmission fought us for an age. We spent 2 hours trying to get the input shaft to seat on the clutch splines and it just wouldn't go. It's been so long since I've had a drivetrain issue that I'd forgotten that the splines on the twin-disk Competition Clutch are on the tight side. Damn near a press fit...and have been a pain in the ass every other time I've worked on it. Legitimately, it was easier to just pull the engine and work on the engine and trans together outside of the car.

So we did.

And then spent another slightly less uncomfortable hour and a half trying to get them mated up outside the car.

Twin disk clutches are a pain in the ass regardless, but this one is WAY on the tight side.

A couple days later, we got back together and threw the now-mated engine and trans back into the car.

Remember when I said pulling the engine was easier? It was 2 hours from turning the first wrench to do up the rest of the bellhousing bolts, to first starting up the car. Another 30 minutes and the exhaust, intake, prop shaft, trans fluid, shifter, coolant bled, etc. With the exception of that damn clutch, I LOVE LOVE LOVE how easy this car is to work on.

All back together.

That afternoon, I took a couple hours to dig into the transmission and a) see how they go together (and realize I'm not cut out for working on them LOL), and b) see what actually broke.

What I found was the counter-shaft (the one offset from the input and output shafts) was *TWISTED* so that the wheels that should move fore and aft on those splines couldn't, jamming it in gear, and locking us out of the 5th / reverse gate all together once we got it unjammed (by yanking on the shifter real hard in grid (rlaugh) ).

Those splines (on the left) should be straight.

Because it wasn't a gear wheel, or a shift fork or syncro, something relatively straight-forward to replace, the transmission has been relegated to the scrap pile. Before I tossed it out, however, it was recommended to me that an actual input shaft makes a FAR more accurate clutch alignment tool than the plastic ones every clutch kit ever comes with, so I cut the last foot or so of the input shaft off to keep as a useful tool.