My 2016 CX-5 Sport starting making a knocking noise on the left side when entering the driveway. The car had about 125K on it at that point. The car also felt like it would wander back and forth in the lane on highways.

When on jack stands, it was obvious the ball joint had failed as the knuckle would click back and forth by pushing against the caliper while pulling on the tie rod end.

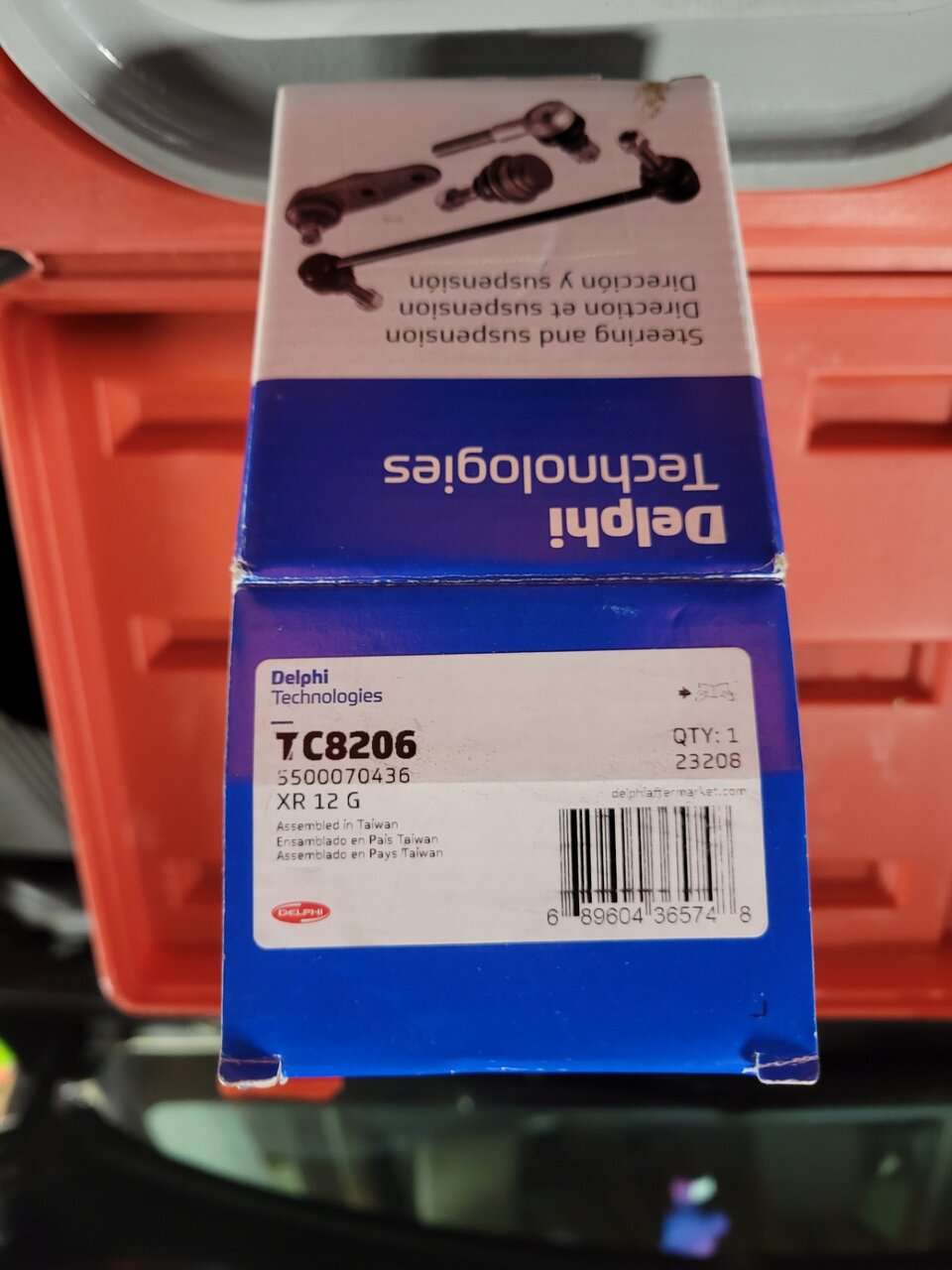

Most of the Mazda forums had posts saying the factory ball joint wasn't replaceable on it's own or some thought it could be done, but there was no verification or photos I could find on the replacement process. On a whim, I ordered the Delphi part #TC8206 from RockAuto for $20. On previous Mazda's, the fully sealed joints always outlived the aftermarket joints with zerk fittings and the Delphi part was the only fully sealed option in stock.

At the same time I ordered this inexpensive Ball Joint Press Kit from Amazon: $28

Most instructions state you have to remove the entire control arm or knuckle/strut assembly to gain access to the joint vertically with the press. I was able to complete the process by only removing the following:

[REMOVAL]

(1) Pull brake hose clip off at strut flange and free brake line.

(2) Remove wheel speed sensor plastic clip on strut and upper clip on frame. Do not attempt to remove sensor bolt. It will likely snap off.

(3) Remove caliper and backing plate as assembly and tie off to the front of the wheel well. I used a metal coat hanger bent into a Z shape. Remove and set aside rotor.

(4) Remove upper 14mm sway bar link nut with the damper

(5) Remove the two strut pinch bolts

(6) Remove the CV shaft nut and tap the axle out while turning the knuckle towards the rear of the vehicle. Once out, tie axle off toward front of opening, just below the brake caliper. Make sure to tie the axle off in a way that doesn't allow the inner joint to separate.

(7) Push the knuckle back into strut temporarily with one strut pinch bolt (no nut needed). Remove ball joint pinch bolt, noting the direction it is installed, then place long punch on top of ball joint stud and hammer downward to separate joint from knuckle. Once free, support knuckle while removing temporary strut pinch bolt, swing knuckle toward rear of opening and tie off by wire to coil spring. Take care to not pull on sensor wire. (Note: tie rod end is still installed).

[PREP]

(1) Wire brush around perimeter of old ball joint, spray lightly with liquid wrench around splines where joint passes through control arm.

(2) Install press with screw upward and cup on bottom that is just slightly larger than ball joint body.

(3) Turn press screw with impact on low or use ratchet. Proceed slowly making sure press and joint are in straight line. Joint should pop out into cup below control arm.

(4) With joint out, lightly wire brush opening in control arm.

[INSTALL]

[1] Lightly lube splines on new ball joint with silicone grease. Wipe light film of grease on opening of control arm. Rub boot with grease film to prevent it from getting snagged when passing through arm

[2] Determine plate and cup configuration needed with press to push evenly on base of ball joint while allowing for stud to come up high enough. Be careful not to continue pressing joint if stud contacts upper part of press before fully seated in control arm. Adjust plates and spacers as needed until rim of ball joint is fully contacting control arm on the bottom.

[3] Inspect all sides of joint under control arm to verify joint went in squarely.

[ASSEMBLY]

(1) Un-tie knuckle assembly and slide knuckle onto new ball joint stud. May require rubber mallet from bottom to fully seat stud. Install pinch bolt to ball joint taking note of bolt direction.

(2) Rotate knuckle toward rear of car, un-tie axle and slide CV shaft back into wheel bearing and loosely install axle nut. Avoid allowing knuckle to pivot outward which might separate inner CV joint until the following step is complete:

(3) Align knuckle with strut, install pinch bolts and nuts loosely.

(4) Install rotor to hub, un-tie brake assembly and slide over rotor, installing two brake backing plate bolts.

(5) Install upper sway link nut with damper.

(6) Install brake line to strut with clip and reattach sensor clips.

(7) Torque all fasteners to spec noting that axle nut requires a two step process of reaching initial torque, backing off 180 degrees and then re-torque to 2nd spec.

Will revisit posting as time allows and add torque ranges for all fasteners required.

Some basic photos of installation:

When on jack stands, it was obvious the ball joint had failed as the knuckle would click back and forth by pushing against the caliper while pulling on the tie rod end.

Most of the Mazda forums had posts saying the factory ball joint wasn't replaceable on it's own or some thought it could be done, but there was no verification or photos I could find on the replacement process. On a whim, I ordered the Delphi part #TC8206 from RockAuto for $20. On previous Mazda's, the fully sealed joints always outlived the aftermarket joints with zerk fittings and the Delphi part was the only fully sealed option in stock.

At the same time I ordered this inexpensive Ball Joint Press Kit from Amazon: $28

Most instructions state you have to remove the entire control arm or knuckle/strut assembly to gain access to the joint vertically with the press. I was able to complete the process by only removing the following:

[REMOVAL]

(1) Pull brake hose clip off at strut flange and free brake line.

(2) Remove wheel speed sensor plastic clip on strut and upper clip on frame. Do not attempt to remove sensor bolt. It will likely snap off.

(3) Remove caliper and backing plate as assembly and tie off to the front of the wheel well. I used a metal coat hanger bent into a Z shape. Remove and set aside rotor.

(4) Remove upper 14mm sway bar link nut with the damper

(5) Remove the two strut pinch bolts

(6) Remove the CV shaft nut and tap the axle out while turning the knuckle towards the rear of the vehicle. Once out, tie axle off toward front of opening, just below the brake caliper. Make sure to tie the axle off in a way that doesn't allow the inner joint to separate.

(7) Push the knuckle back into strut temporarily with one strut pinch bolt (no nut needed). Remove ball joint pinch bolt, noting the direction it is installed, then place long punch on top of ball joint stud and hammer downward to separate joint from knuckle. Once free, support knuckle while removing temporary strut pinch bolt, swing knuckle toward rear of opening and tie off by wire to coil spring. Take care to not pull on sensor wire. (Note: tie rod end is still installed).

[PREP]

(1) Wire brush around perimeter of old ball joint, spray lightly with liquid wrench around splines where joint passes through control arm.

(2) Install press with screw upward and cup on bottom that is just slightly larger than ball joint body.

(3) Turn press screw with impact on low or use ratchet. Proceed slowly making sure press and joint are in straight line. Joint should pop out into cup below control arm.

(4) With joint out, lightly wire brush opening in control arm.

[INSTALL]

[1] Lightly lube splines on new ball joint with silicone grease. Wipe light film of grease on opening of control arm. Rub boot with grease film to prevent it from getting snagged when passing through arm

[2] Determine plate and cup configuration needed with press to push evenly on base of ball joint while allowing for stud to come up high enough. Be careful not to continue pressing joint if stud contacts upper part of press before fully seated in control arm. Adjust plates and spacers as needed until rim of ball joint is fully contacting control arm on the bottom.

[3] Inspect all sides of joint under control arm to verify joint went in squarely.

[ASSEMBLY]

(1) Un-tie knuckle assembly and slide knuckle onto new ball joint stud. May require rubber mallet from bottom to fully seat stud. Install pinch bolt to ball joint taking note of bolt direction.

(2) Rotate knuckle toward rear of car, un-tie axle and slide CV shaft back into wheel bearing and loosely install axle nut. Avoid allowing knuckle to pivot outward which might separate inner CV joint until the following step is complete:

(3) Align knuckle with strut, install pinch bolts and nuts loosely.

(4) Install rotor to hub, un-tie brake assembly and slide over rotor, installing two brake backing plate bolts.

(5) Install upper sway link nut with damper.

(6) Install brake line to strut with clip and reattach sensor clips.

(7) Torque all fasteners to spec noting that axle nut requires a two step process of reaching initial torque, backing off 180 degrees and then re-torque to 2nd spec.

Will revisit posting as time allows and add torque ranges for all fasteners required.

Some basic photos of installation: