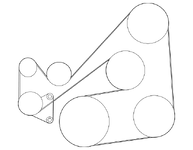

I plan to replace the serpentine belt on my 2013 Mazda5 (2.5l engine) 144k Miles. I'm curious what people believe should be included in the replacement. It looks like there are two idler pulleys (one grooved, one smooth) and a tensioner pulley.

-Is it recommended to replace all three pulleys at the same time as the belt?

-Is there a preferred brand for the belt, idlers, and Tensioner?

-Is mixing and matching brands discouraged? I like the Gates belt, and the price is reasonable, but they are proud of their tensioner.

-Anything else I should replace while I'm at it?

I found a link in the resources with a good tip for installing the new belt from above. Post here. Video here.

Also, found a link for bearing replacement in the grooved Idler here. This saves you from needing to buy the whole idler assembly $$$$.

If you are replacing the Tensioner Assembly, it appears to be easier from below. You can find a good video for the 2.5L engine here.

Another thorough video is here.

Edit: Added links to help future searches

-Is it recommended to replace all three pulleys at the same time as the belt?

-Is there a preferred brand for the belt, idlers, and Tensioner?

-Is mixing and matching brands discouraged? I like the Gates belt, and the price is reasonable, but they are proud of their tensioner.

-Anything else I should replace while I'm at it?

I found a link in the resources with a good tip for installing the new belt from above. Post here. Video here.

Also, found a link for bearing replacement in the grooved Idler here. This saves you from needing to buy the whole idler assembly $$$$.

If you are replacing the Tensioner Assembly, it appears to be easier from below. You can find a good video for the 2.5L engine here.

Another thorough video is here.

Edit: Added links to help future searches

Last edited: