What are you referring to as a "local B&M store"? Selection at Home Depot/Lowes is going to be poor, probably non-existent for things like metric all-thread.

Try your local Fastenal or similar, they almost certainly will have (or can get) whatever you need, in the quantities you need.

Awesome find/suggestion! This is exactly what I'm looking for. I only know of Home Depo/Lowes and metric is near non-existent. I've always been under the impression hardware stores like Fastenal only exists in the South and Mid-West where there are more DIY'ers as most farmlands and manufacturing are located out there. I'm super excited Fastenal is a chain that exist not too far from me! This is now one of the my favorite stores! Do you know of any other good stores for DIY'ers? E-beer for you (drinks)

For reference, MCP sells jam nuts for ~$5 EACH (granted grade 8 or class 10.9), while Fastenal have approved vendors selling jam nuts for <$.50 EACH (grade 4). WOW!... Still have to figure out the threaded rod. They only sell 1 meter length (cut to size, good for trial and error I suppose) but cost more than 2 280mm from MCP.

i understand all that, but with a car like the mazda5, as soon as you load it up with 2-3 people and a driver, or load it up for a road trip, all that preload adjustment goes right out the window. I would still recommend either OEM links, or the heavy duty racing beat links.

Funny you mention load variation! This is one of the reason why I am going after THK, specifically. Why do you recommend Racing Beat over the other aftermarket?? Purely my opinion but Racking Beat is junk. I'd much rather suggest CS or JBR (not sure if they offer one) or something of that line. If you read up on PowerGrid's links, you'll see every single review says they are awesome. You can have adjustability WITHOUT any noise. Secrete is in the balls. The easy way to do it is to buy PowerGrid but they cost ~$190 (or something in that ball park) but what fun and learning experience (and savings) would you get out of that…

BTW, say 4 people x ~150 lbs = 600lbs. This is cabin weight so gets distributed between the front and rear axle. The springs are rated, crap I don't recall -say ~400lbs/in??, so the car is probable lowed a few fractions of an inch perhaps?

Couple of points:

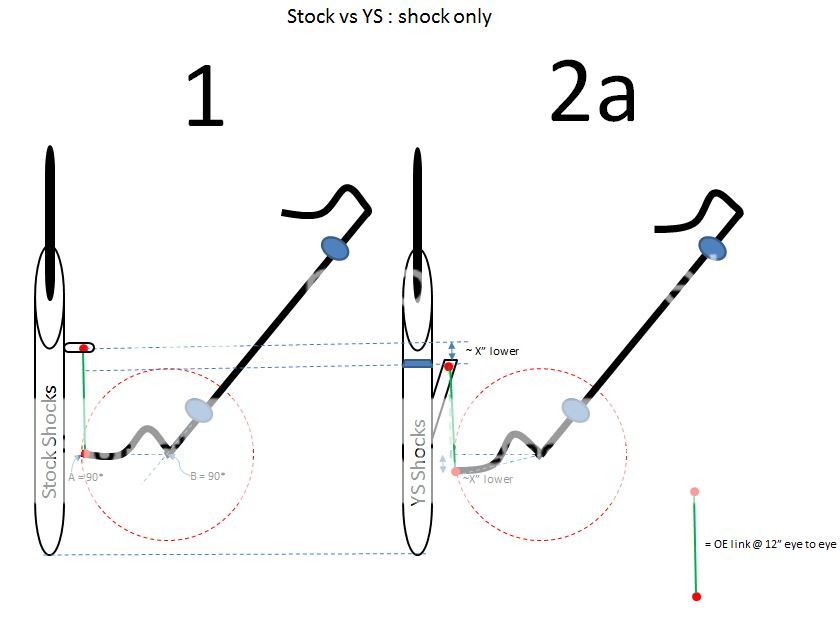

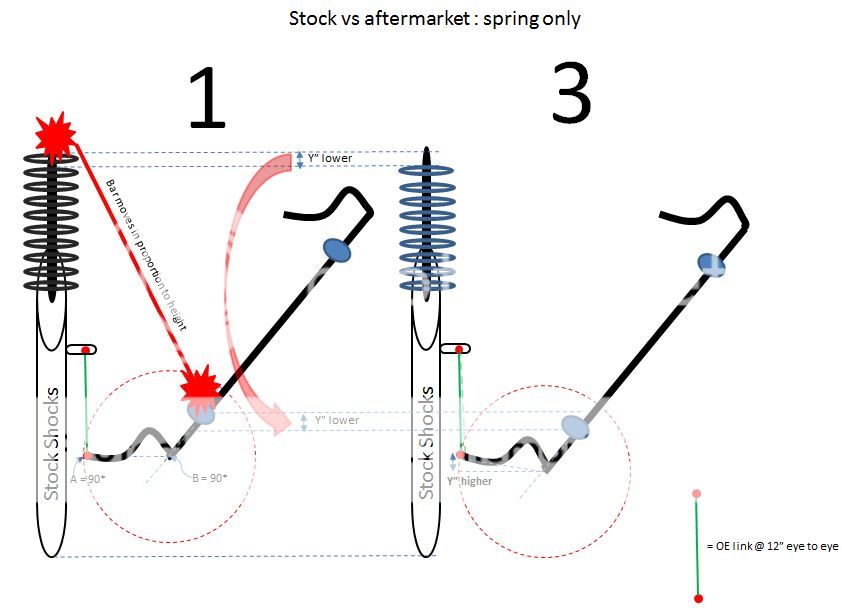

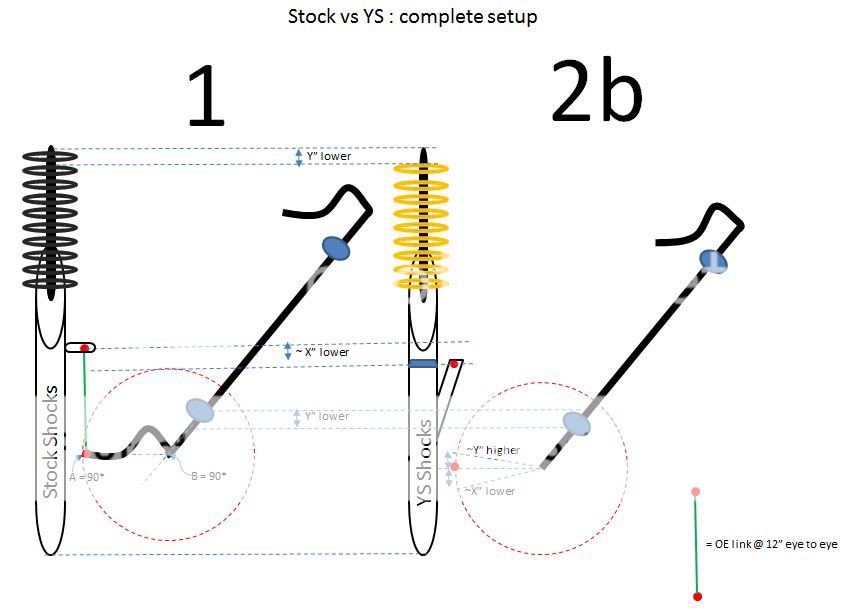

-The YS end link mount points are lower, guestimate by ~1", than the mounts on the stock shock body. This would put a lot of pre-load on the FSB. Granted, this changes after lowering it some. YS probably considers this fact so start with a lower mounting point.

-OEM links are quite good and do not create noise and can account for load b/c it is a ball design that offers a good, guestimate 10-15%, rotational movement. This allows the link to still work properly when under load yet no noise (unless dry grease)! If you are lowered AND on stock links, this would put a lot of stress on them. Whereas the conventional design ones will lead to pre-load right out of the box and should only be used on racing applications where static weight fo the car does not change.

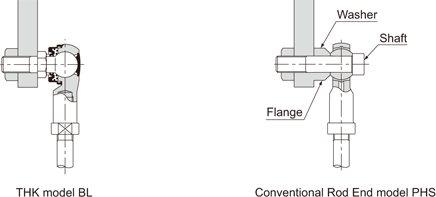

-THK joints work just like OEM but offer the ability to stick in whatever rod length you choose AND is built tougher, which benefits if you use a stiff bar.

-Pre-load is bad, nuff said.

-Re-read post #3 to understand the difference between conventional links (Racing Beat) vs ball joint (THK and OEM) links and the advantages of ball links.

I firmly believe a car can be lowered, handle well, and still ride nice. I also believe that the suspension works as good as it’s weakest link (doh). I'm trying my best to balance my setup. The biggest unknown being how well these YS perform.