ser_smokes_alot

Member

First post here, but I think I can help you guys out. Last time I had my speed3 up on the rack with the wheels off, I noticed the front calipers appear to be the same as the front Volvo XC-90 calipers. Well I happen to be a Volvo tech.

Remove brake fluid reservoir cap. Wrap a rag around it in case fluid comes out.

Break free lugs.

Jack car up and place on stands. (don't be stupid, chock wheels etc for safety)

Remove wheel.

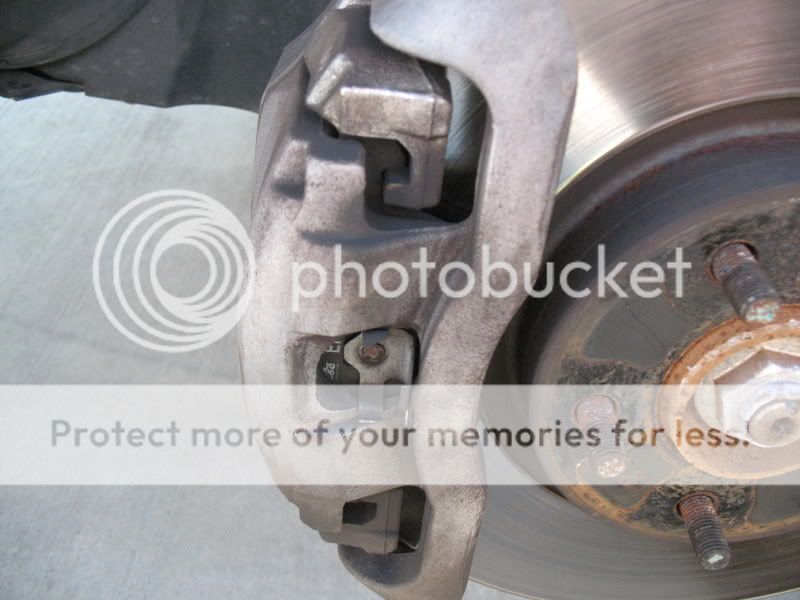

In order to get the caliper off you first need to remove the spring. To do this you must pry between the middle of the spring, and the small metal plate that is attatched to the outer pad.

Once the center clip pops out you just wiggle and fanangle the spring out.

Now you must press back the piston. I use either a small pry bar and/or BIG channel locks.

Once the piston is pushed back partially you can remove the 2 slider pins the hold the caliper. These should be covered with black caps. I believe they are a 7mm allen.

Now remove and hang the caliper. Finish pressing in the piston with channel locks.

Remove the pads.

Paste/lube the backing plate of the brake pads and slider pins.

Install new pads.

Put caliper back on bracket. DO NOT OVER TIGHTEN. Very very snug is good. Maybe 30-50 ft/lbs.

Finangle spring back on.(This is the fun part) This is very important. It will hold in the outer pad.

Install wheel.

DON'T FORGET TO PUMP THE BRAKES BEFORE DRIVING!!!

Congradulations you just changed your brake pads! (yippy)

Remove brake fluid reservoir cap. Wrap a rag around it in case fluid comes out.

Break free lugs.

Jack car up and place on stands. (don't be stupid, chock wheels etc for safety)

Remove wheel.

In order to get the caliper off you first need to remove the spring. To do this you must pry between the middle of the spring, and the small metal plate that is attatched to the outer pad.

Once the center clip pops out you just wiggle and fanangle the spring out.

Now you must press back the piston. I use either a small pry bar and/or BIG channel locks.

Once the piston is pushed back partially you can remove the 2 slider pins the hold the caliper. These should be covered with black caps. I believe they are a 7mm allen.

Now remove and hang the caliper. Finish pressing in the piston with channel locks.

Remove the pads.

Paste/lube the backing plate of the brake pads and slider pins.

Install new pads.

Put caliper back on bracket. DO NOT OVER TIGHTEN. Very very snug is good. Maybe 30-50 ft/lbs.

Finangle spring back on.(This is the fun part) This is very important. It will hold in the outer pad.

Install wheel.

DON'T FORGET TO PUMP THE BRAKES BEFORE DRIVING!!!

Congradulations you just changed your brake pads! (yippy)